About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2019-05-21 16:06:00

date:2019-05-21 16:06:00

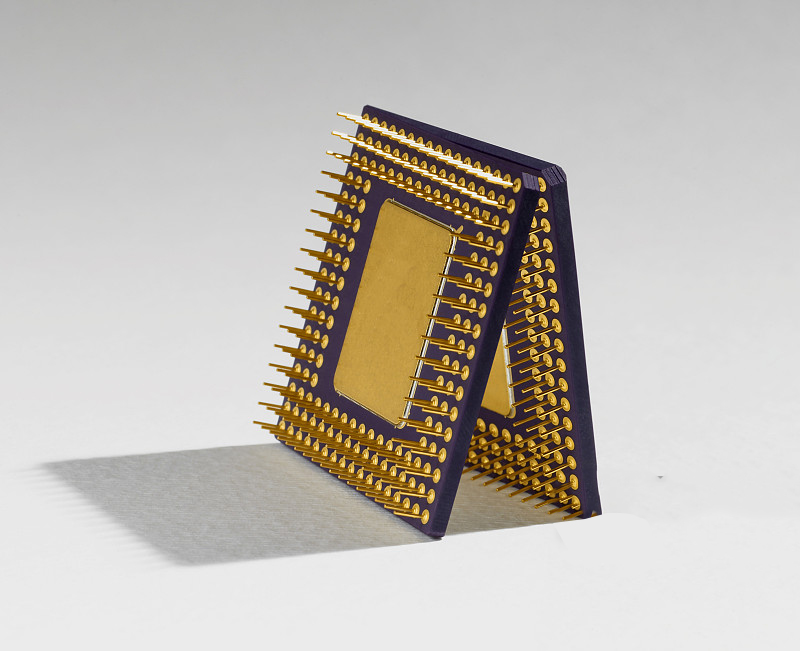

BGA PCB board assembly

Definition: The A full name of BGA is BALL Grid Array, which is a kind of encapsulation method for integrated circuits using organic carrier boards.

Advantage:

1. Small encapsulation area

2. Function is increased, the number of pins is large

3. PCB board can self-center when it is dissolved, easy to tin

4. High reliability

5. Good electrical performance and low overall cost.

PCB boards with BGA generally have many small holes. Most customers have BGA holes. The hole diameter is 8-12 mil. The distance between the surface of the BGA and the hole is 31.5 mil, which is generally not less than 10.5 mil. BGA. The vias are required to be plugged, the BGA pads are not allowed to be inked, and the BGA pads are not drilled.

The I/O terminals of the BGA encapsulation are distributed in the form of arrays of circular or columnar solder joints under the encapsulation. The advantage of the BGA technology is that although the number of I/O pins is increased, the pitch of the pins is not reduced but increased. Increased assembly yield; although its power consumption increases, BGA can be soldered with a controlled collapse chip method to improve its electrothermal performance; thickness and weight are reduced compared to previous packaging techniques; parasitic parameters are reduced, The signal transmission delay is small, the frequency of use is greatly improved; the assembly can be used for coplanar welding with high reliability.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]