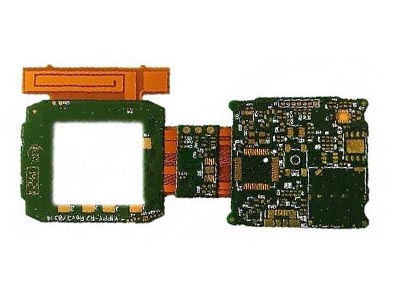

Flexible PCB Boards

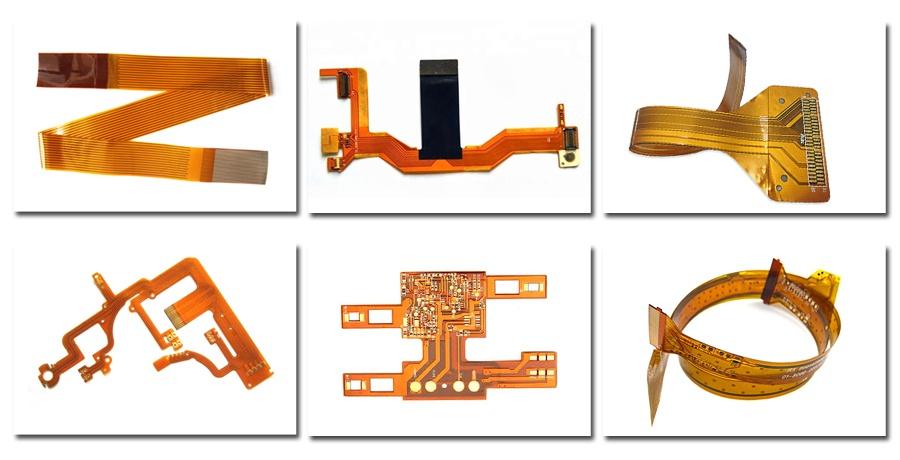

Flexible pcb circuit board

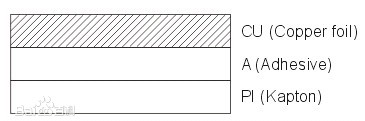

Flexible pcb circuit board is also called flexible circuit board ( FPC ) for short. It is mainly composed of CU (Copper foil) (ED or RA copper foil), A (Adhesive) (acrylic and epoxy resin thermosetting adhesive) ) And PI (Kapton, Polyimide) (polyimide film) composed of circuit boards have many advantages such as space saving, weight reduction and high flexibility. They are widely used in production and life, and the market is still expanding.

| Flex PCB Capability | ||

| Items | Type | Normal Manufacturing Capability |

|

Standard Deliverable |

Inspection Std. |

IPC-6013 Class2, IPC-A-600G Class2 |

| Test Std. | IPC-TM-650,GB/T4677-2002 | |

|

Material |

DuPont |

AL9111R, AP9121R, AP9131R, AP8525R |

| Panasonic | R-F775 11RB-M, R-F775 22RB-M, R-F775 21RB-M | |

|

Taiflex |

NDIR050513HJY,IDIR051013HJY,NDIR100520HJY,THK D200520JY | |

|

Process capacity |

Layers | 0-14 |

| Thickness | 0.07-4.0mm | |

| Max dimension | 10X18 Inch | |

| Min precision Of Dim | ±4mil | |

| Min diameter of holes | 4mil (Laser drill); 8mil(mechanical drill) | |

| Aspect ratio | 10:1 | |

|

Min trace width/sp ce outer layer(0.5OZ ) |

3.0/3.0mil |

|

|

Min trace width/space outer layer(1OZ ) |

3.5/3.5mil |

|

|

Min trace width/space outer layer(2OZ ) |

5/5mil |

|

|

Min trace width/space inner layer(0.5OZ ) |

3.5/3.5mil |

|

|

Min trace width/space inner layer(1OZ ) |

4/4mil |

|

|

Min trace width/space wtidth of gridding circr |

5/5mil |

|

|

Min trace width/space wtidth of out layer |

5/5mil(1/3、1/2oz copper);6.5/5mil(1oz copper); 8/5.5mil(2oz copper); |

|

|

Min distance Between drilling&conductor(via holes) |

7mil(2layers);9mil(3~6Llayers);11mil(≥7layers) |

|

|

Min distance Between drilling&conductor(compon ent holes) |

10mil(2layers);12mil(3~6Llayers);14mil(≥7layers) |

|

|

|

Min distance Between drilling&conductor(buried &blind holes) |

7mil |

|

Min ring of inner layer(via holes) |

5mil(≤6 Layers) ;8mil(>8Layers) |

|

|

Min ring of inner layer(component holes) |

8mil(≤6Layers) ;11mil(>8Layers) |

|

| The vias to the coalescent location of rigid and flex |

1mm |

|

| HDI board | 1+n+1 | |

|

Surface treatment |

Plating Gold(Hard gold) | Normal:0.25-0.76um;Hard gold:0.76-2um; |

|

ENIG |

Ni:3--8um,Au:0.05-0.1um |

|

|

Immersion Tin |

0.80-1.20um |

|

|

Immersion Silver |

0.10-0.30um |

|

|

0SP |

0.15-0.30um |

|

| HASL |

2-40um |

|

| HASL lead free |

2-40um |

|

| Silver ink |

10-25um |

|

|

Selective surface finishing |

ENIG+GOLD Finger; ENIG+HASL; ENIG+OSP; Soft gold+ GOLD Finger; Flash gold+HASL; immersion Tin+gold finger; Immersion sliver+gold finger; OSP +gold finger; Silver ink+Plating gold; Silver ink+ENIG. |

|

|

Min. bended radius |

single side flex | 3-6 times the flex thickness |

|

double sides flex |

6-10 times the flex thickness |

|

|

multi-layers flex |

10-15 times the flex thickness |

|

|

dynamic bending |

20-40 times the flex thickness |

Structure of Flexible pcb circuit board

* CU (Copper foil): E.D. and R.A. copper foil

* Cu copper layer, copper skin is divided into RA, Rolled Annealed Copper and ED, Electrodeposited. The two have different characteristics due to different manufacturing principles. ED copper has low manufacturing cost but is fragile. It is used for Bend (bending) or Driver (drilling). ) When the copper surface is easy to break. RA copper has high manufacturing cost but good flexibility, so Flex PCB copper foil is mainly RA copper.

* A (Adhesive): Acrylic and epoxy resin thermosetting adhesive

* Adhesive is composed of two major systems: Acrylic and Epoxy.

* PI (Kapton): Polyimide (polyimide film)

* PI is the abbreviation of Polyimide, called Kapton in DuPont, and the unit of thickness is 1/1000 inch lmil. The characteristics are thinness, high temperature resistance, strong chemical resistance, and good electrical insulation. The current Flex PCB insulation layer has welding requirements. Kapton.

The characteristics of Flexible pcb circuit board

1. Reduce the size of the application product, save space, greatly reduce the weight, increase the function, and reduce the cost.

2. It is highly flexible and can be wired in three dimensions, and the shape can be changed according to space constraints.

3. Foldable without affecting signal transmission, anti-static interference.

4. High and low temperature resistance, flame resistance.

5. Stable chemical changes, high stability and reliability.

6. Providing more related solutions for related products can reduce assembly man-hours and errors, and increase the service life of related products.

The role of Flexible pcb circuit board

1. The function of the soft board can be divided into four types, namely lead wire, printed circuit, connector and multi-function integrated system

2. Lead wires: connections between rigid printed circuit boards, three-dimensional circuits, movable circuits, and high-density circuits.

3. Printed circuit: high-density thin three-dimensional circuit

4. Connector: low-cost connection between hard boards

5. Multi-function integration system: integration of hard board lead wires and connectors

Application of Flexible pcb circuit board

Flexible pcb circuit boards are widely used in commercial electronic equipment, car dashboards, printers, hard disk drives, floppy drives, fax machines, car mobile phones, general phones, notebook computers, cameras, video cameras, CD-ROMs, Hard disks, watches, computers, cameras, medical equipment and other electronic products and equipment.

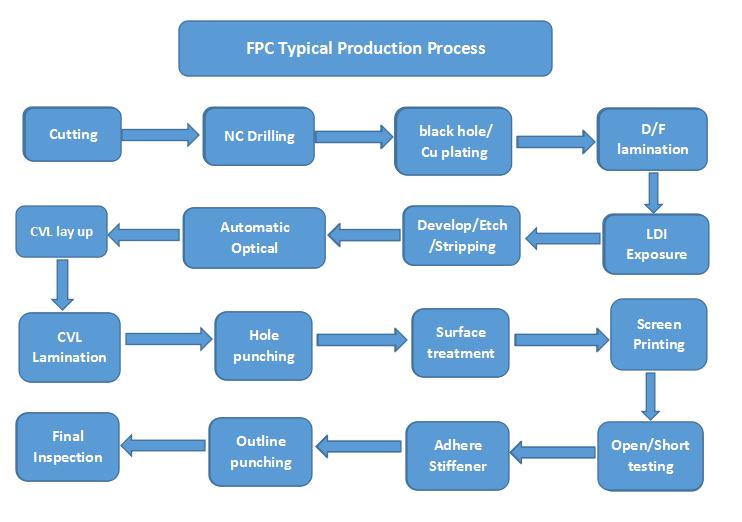

How to make flexible PCB board ?

Making Flexible PCB flow chart from multilayer flexible pcb factory, want to know more, welcoem to contact us.

FASTPCBA Service Center

FASTPCBA is Professional 20 Years PCB / PCBA Manufactuer in China, especially more than 80% circuit board are exported to oversea market. We offer 24*7 hours quotation service and engineering support. Offering: 1) PCB Assembly (including Components Sourcing & Testing) 2) Rigid PCB (1~48Layer) 3) Flexible PCB 4) Rigid-flex PCB 5) Aluminum PCB If you have any PCB projects, welcome to contact us. We sincerely hope to cooperate with you.

Products related to this product / Related Products

- Cheap flex pcb pcb printing company custom flexible pcb quick tu

- A copper trace pattern bonded to a flexible substrate with or without a flexible overlay is called cheap flex pcb or flexible circuit PCB. These flexible circuits can be manufactured using the same components to make rigid electronic circuits, the only difference is that the flexible circuits can be molded into any desired shape based on the product's packaging without affecting connectivity.

- DIY flexible pcb manufacturing fast pcb fabrication make pwb

- DIY pcb mean the pcb do it yourself, for beginner or you just have small volume pcb prototype to produce, no MOQ limit, we support all pcb project, no MOQ request, flexible

Related information

| I want to comment: | |

| *Content: |

(Content up to 500 words, 1000 characters) |

| Verification Code: | Invisibility?! |

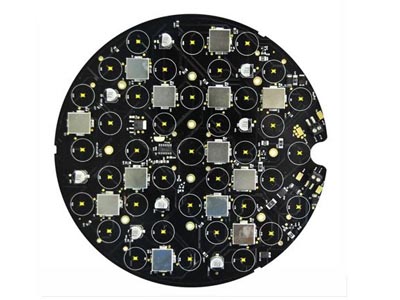

samples

PCB Assembly

Multilayer PCB

Rigid-Flex PCB

Flexible PCB

HDI PCB

High Frequency PCBs

Gold-Plated PCB

Aluminum PCB

PCBA Board

PCB Prototype

Components

Add WeChat:18784674559

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

3/F. 1/B, 18-2 Yuquan East Rd. Yulv Village.

3/F. 1/B, 18-2 Yuquan East Rd. Yulv Village.  F:86-18784674559

F:86-18784674559

Altogether-article comment【I want to comment】