About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2021-05-20 17:02:12

date:2021-05-20 17:02:12

In smt assembly, many factories will more or less encounter SMT processing technology problems. For example, we will discuss some PCBA processing technology problems in the process of CCGA(Ceramic Column Grid Array) package assembly that we are going to discuss today. Let's analyze it.

Overview:

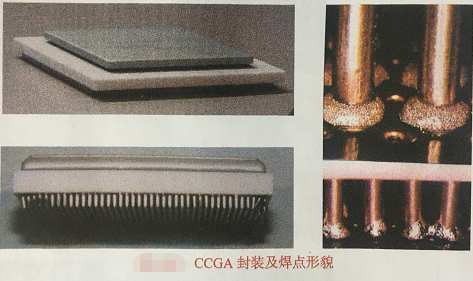

The CCGA package and solder joint morphology are shown in the figure below, which is another form of CBGA when the ceramic size is larger than 32mm×32mm. The difference from CBGA is that it is not solder balls that are fully connected under the ceramic carrier, but 90Sn/10Pb plastic columns (liquid phase temperature range is 183~213℃). The solder column array can be fully distributed or partially distributed. The diameter of the common solder column is about 0.5mm, the height is about 2.21mm, and the typical pitch of the array is 1.27mm. Due to its large heat capacity, the process of reflow soldering is very challenging.

Process points:

The main points of the CCGA mixing process (lead-free solder paste soldering with lead CCGA) are as follows.

(1) Solder paste printing

There is no special requirement, generally 0.15mm thick steel mesh is used.

(2) Patch

Its self-alignment ability is much worse than BGA. Generally, even if the BGA is offset by 75%, the position can be automatically calibrated, but the CCGA patch allows up to 25% offset. If it exceeds, it may cause the solder column to bridge the adjacent pad solder paste.

(3) Reflow welding temperature curve

Research shows that lead-free solder paste can be used to solder leaded CCGA, and the minimum soldering peak temperature should reach (235±5) ℃

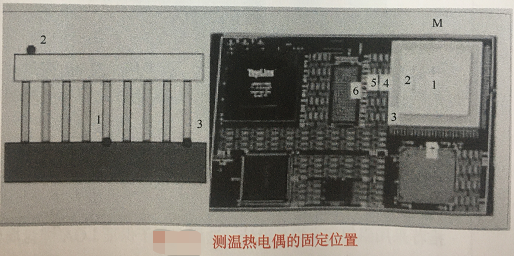

The fixed position of the temperature measuring thermocouple is shown in the figure below.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]