About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2022-03-29 15:45:39

date:2022-03-29 15:45:39

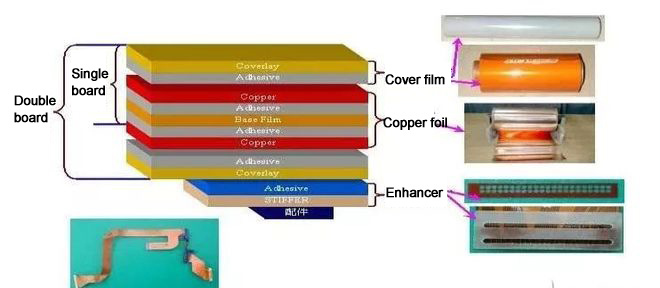

A flexible circuit board is a highly reliable and excellent flexible printed circuit made of a flexible insulating substrate such as polyimide or polyester film. It has the characteristics of high wiring density, light weight, thin thickness and good bendability.

Flexible printed circuit boards are also divided into single-sided, double-sided and multi-layer boards. The flexible circuit board is mainly used in the connection parts of electronic products, and its advantage is that all circuits are configured. Eliminates connection workers for redundant cables; can improve softness. Strengthen the assembly of three-dimensional space in a limited space; it can effectively reduce the volume of the product. Increases portability; also reduces the weight of the final product.

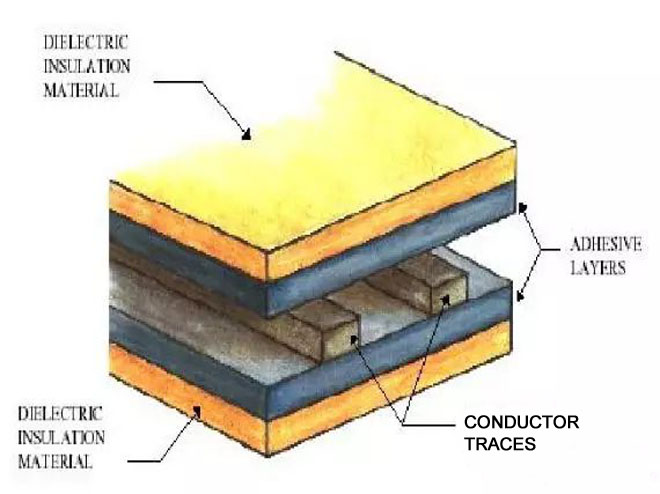

1. Basic structure of flexible circuit board

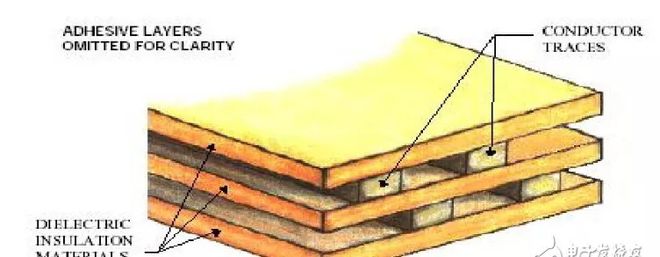

From the analysis of the basic structure of the flexible printed circuit board, the materials that constitute the flexible printed circuit board include insulating substrates, adhesives, metal conductor layers (copper foil) and cover layers.

1.1 Copper foil substrate

Copper foil: basically divided into two types: electrolytic copper and rolled copper. Common thicknesses are 1oz 1/2oz and 1/3oz

Substrate film: Common thicknesses are 1mil and 1/2mil.

Glue (adhesive): The thickness is determined according to customer requirements.

1.2 Overlay Protective Film

Cover film protective film: for surface insulation. Common thicknesses are 1mil and 1/2mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Release paper: avoid the adhesive from adhering to foreign matter before pressing; easy to operate.

1.3 Reinforcing plate

Reinforcing plate: Reinforcing the mechanical strength of FPC, facilitating surface mounting operations. Common thicknesses are 3mil to 9mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Release paper: Avoid the adhesive from sticking to foreign matter before pressing.

EMI: Electromagnetic shielding film, which protects the circuit in the circuit board from interference from the outside world (strong electromagnetic area or susceptible area).

2. Flexible circuit board production process

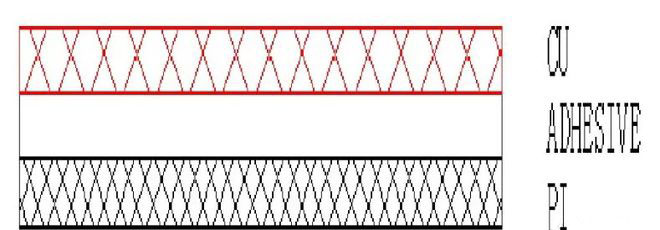

2.1 Single-sided flexible circuit board

Single-sided flexible circuit board composition diagram

Cutting material → drilling → sticking dry film → alignment → exposure → developing → etching → stripping → surface treatment → covering film → pressing → curing → surface treatment → immersion nickel gold → character printing → shearing → electrical measurement → punching Cutting → Final Inspection → Packing → Shipping

single-sided flexible circuit board stack

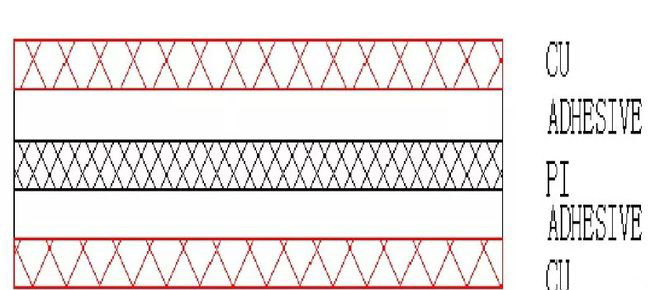

2.2 Double-sided flexible circuit board

Material cutting → drilling → PTH → electroplating → pretreatment → dry film sticking → alignment → exposure → development → pattern plating → film release → pretreatment → dry film sticking → alignment exposure → development → etching → film release → surface treatment → Applying cover film → Pressing → Curing → Immersion Nickel Gold → Character Printing → Cutting → Electrical Testing → Punching → Final Inspection → Packaging → Shipping

double-panel stackDouble-sided flexible circuit board stack

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]