About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2019-07-19 14:39:28

date:2019-07-19 14:39:28

For China pcb manufacturer,PCBA penetration tin requirements and factors affecting the penetration tin

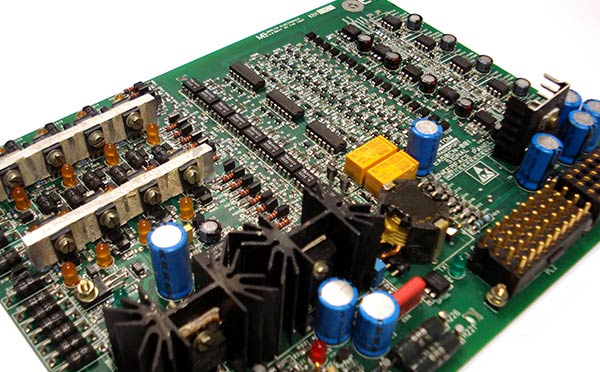

In the through-hole plug-in craft, the PCB board is not well-penetrated, which is prone to problems such as virtual welding, tin cracking or even missing parts. For China pcb manufacturer,craft engineer is very headache about the problem .

Next,FASTPCBA tidy up some factors affecting the penetration tin of PCBA.

First, PCBA penetration tin requirements

According to the IPC standard, for China pcb manufacturer,the PCBA penetration requirements for through-hole solder joints are generally above 75%, that is to say, the solder-on-board surface appearance inspection is not less than 75% of the aperture height (board thickness), PCBA penetration tin is suitable from 75% to 100%. The plated through hole is connected to the heat dissipation layer or the heat conduction layer for heat dissipation function, and the PCBA penetration tin requires more than 50%.

Second, factors affecting PCBA penetration tin

Poor PCBA penetration tin is mainly affected by factors such as materials, wave soldering crafts, fluxes, and manual welding.

1, Material

High-temperature melting tin has strong permeability, but not all welded metal (PCB board, components) can be penetrated . For example, aluminum metal, its surface will automatically form a dense protective layer, and the different internal molecules structure also makes it difficult for other molecules to penetrate. Second, if there is oxide layer on the surface of the metal to be welded, it will also prevent the molecules penetration. Flux treatment or gauze to cleaning is usually used.

2, Wave soldering craft

The poor PCBA penetration is directly related to the wave soldering craft, re-optimizing the poor penetration parameters such as wave height, temperature, soldering time or moving speed. First, the orbital angle is appropriately lowered a little, and the height of the wave is increased, to increase the contact amount of the liquid tin with the soldered end; then, the temperature of the wave soldering is increased. Generally, the higher the temperature, the stronger the permeability of tin, but temperature of the components can withstand should be considered; finally, the speed of the conveyor belt can be reduced, the preheating and welding time can be increased, making the flux can fully remove the oxide, infiltrate the welding end, and increase the amount of penetration tin.

3, Flux

Flux is also an important factor affecting the poor penetration tin of PCBA. Flux mainly plays the role of removing the surface oxide of PCB and components and preventing reoxidation during soldering. The flux is not well selected, the coating is uneven, and the amount is too small, which will both lead to poor tin penetration. The well-known brand of flux can be selected, the activation and infiltration effects will be higher, and the oxides that are difficult to remove can be effectively removed. The flux nozzles should be inspected, and the damaged nozzles should be replaced in time to ensure that the surface of the PCB board is coated with an appropriate amount of flux. Let the flux play the role of welding effect.

4, Manual welding

In the actual plug-in welding quality inspection, a considerable part of the weldment only has the surface solder formed into a taper, and there is no tin penetration in the via hole. It is confirmed that many of these parts are solder joints in the functional test , which is more in the manual plug-in. The reason is that the temperature of the soldering iron is not appropriate and the soldering time is too short.

For China pcb manufacturer, poor penetration of PCBA can easily lead to solder joint problems and increase the cost of rework. If the requirements for PCBA penetration tin are relatively high, the welding quality requirements are strict, and selective wave soldering can be used, which can effectively reduce the problem of poor PCBA penetration tin.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]