About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2019-07-01 14:37:00

date:2019-07-01 14:37:00

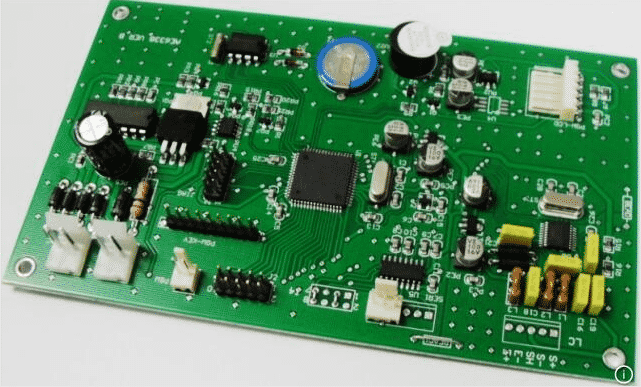

For pcb assembly, analysis of common problems in SMT process

In the SMT processing factory, we often encounter some common problems, such as short-circuiting of components, soldering of solder balls, and virtual welding. We find some of the common reasons for these common problems in SMT processing from the following common reasons. FASTPCBA also welcomes peers to make supplement;

First, the cause and solution of the short circuit

causes

Welding pad design is too wide / too long

No solder mask film between welding pads

Pad gap is too small

Solutions

Modify PCB Layout

Second, the reasons and solutions for tin beads

causes

Solder mask film printing is not good, solution: PCB incoming control

The welding pad has moisture or dirt. solution: Remove water or dirt from the PCB.

Third, the cause and solution of the virtual welding

causes

The pressure of printing solder paste is too high, the solution: reduce the pressure of the printing blade

Tin powder oxidation, flux deterioration, replacement of solder paste

Preheating zone is heating up too fast, adjusting furnace temperature curve

Track speed is too fast, the solution: reduce the speed of reflow soldering track

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]