About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2021-05-12 15:42:29

date:2021-05-12 15:42:29

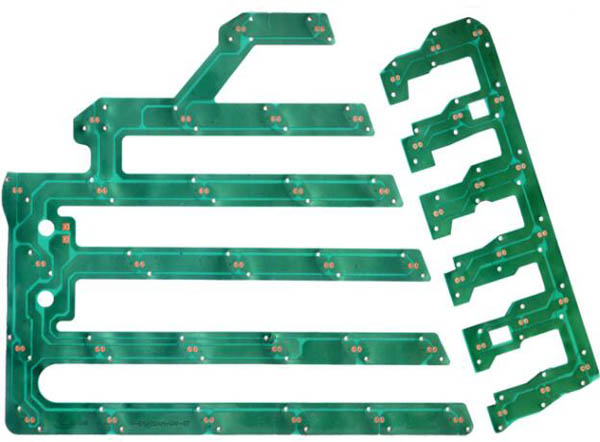

FPC soft boards are widely used in electronic products. FPC is a highly reliable flexible printed circuit board made of polyimide or polyester film as the base material. Since FPC has low mechanical strength and is easy to crack, it is necessary to fit reinforcing materials to strengthen the strength of FPC.

The types of FPC reinforcing sheets include steel sheet, FR4, PI and aluminum sheet, etc., to solve the flexibility characteristics of FPC, improve the strength of the plug-in part, and facilitate the overall assembly of the product.?So, what are the mounting methods of the FPC flexible circuit board reinforcement sheet? FASTPCBA will give you a detailed explanation.

Three ways to strengthen the soft board

1. Manual FPC reinforcement placement method

Due to the wide variety of FPCs, different sizes, and various types of reinforcing sheets to be attached, manual methods are currently the main method, but manual hand-attaching methods are slow and poor in accuracy, which can no longer be used for FPC flexible circuit boards with more panels. Meet production needs.

2. Stamping FPC reinforcement method

The reinforcement board is stamped and formed by stamping equipment, and the stamped reinforcement board is attached to the FPC flexible circuit board. In order to realize the bonding process, the FPC needs to be transported to the stamping equipment. In the prior art, the FPC needs to be placed on the transfer tray, and the transfer tray is transported to the stamping equipment by linear motion. In order to make the FPC align with the reinforced plate that has been stamped and formed, multiple linear motions are required to complete the alignment process. , The adjustment steps are more complicated and time-consuming.

3. Suction sticking FPC reinforcement method

The gantry structure is adopted, and the FPC flexible circuit board is transported to the placement position by means of a jig by rail transportation, the placement head is positioned at the MARK point, and the reinforcing sheet is absorbed on the automatic feeder, and the compensation is performed through visual recognition. The strong film is compensated for precise placement. This method has high placement accuracy and fast speed, and can fully meet the needs of mass production.

The above is the introduction of "Three Ways to Reinforce FPC Flexible Board" compiled by FASTPCBA. I hope it will be helpful to everyone. If there are any unclear points about FPC Flexible Board, PCB Manufacturing and PCB Assembly, please contact us for your answer. .

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]