About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2021-09-01 18:10:23

date:2021-09-01 18:10:23

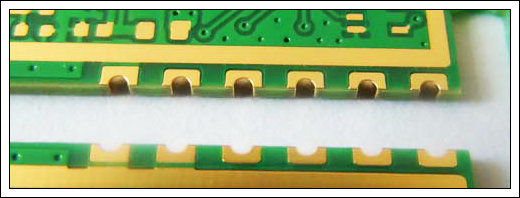

A half hole printed circuit board refers to a hole (drill, gong groove) that is drilled and shaped, and then half of the metalized hole (groove) is retained. In order to control the production of metal half-hole plates, some measures are usually taken due to process problems at the intersection of metallized half-holes and non-metallized holes. In the current saturated state of circuit board proofing factories, there are not many board factories willing and able to produce half-hole boards. Honglian Circuit is one of the few manufacturers. Metallized half-hole PCBs have fewer applications in various industries than PCBs. The metallized half-hole is easy to pull out the sinking copper in the hole when milling, so the scrap rate is very high.

For the inversion of the front, to prevent the quality of the product and the need to make corrections in the subsequent process, the production process of this type of board is processed according to the following process: a drilling (drilling, gong groove-plate surface plating- --External light imaging--Pattern plating--Drying--Semi-hole processing--Film removal, etching, and tin removal--Other processes--Shape

Metallized Half Hole PCB

The specific metallized half-holes are handled in the following way: all metallized half-hole PCB holes must be drilled in the pattern after plating, and before etching, drill a hole at the intersection of both ends of the half hole.

1) The engineering department formulates the MI process according to the process,

2) The metal half-hole is drilled during the first drilling (or gong out), after the image is plated, and before the etching, the second-drilling half-hole must be considered whether the copper will be exposed when the gong groove is shaped, and the drilled half-hole must be moved into the unit.

3) Right hole (drilled half hole)

a. Finish drilling first, then flip the board (or mirror direction); drill the left hole

b. The purpose is to reduce the pulling of the hole copper in the half hole by the drill, resulting in the lack of hole copper.

4) The size of the drill nozzle for drilling the half hole depends on the spacing of the contour lines.

5) Draw the solder mask film, use the gong space as a stop point and open the window to increase 4mil treatment.

According to FASTPCBA's many years of PCB production experience, it is recommended that the designer make modifications when designing the circuit and change the distance from the edge line to the hole center. Generally, the design is to place the hole center on the edge line and move the control center down, such as the hole. The diameter is 1.4mm, the distance between the two holes is 2.54mm, the board edge line is 0.33mm from the center of the through hole, and the board thickness is 0.6mm. The angle between the tangent of the cut point of the wall and the path of the milling cutter was 90 degrees before, and this time it was about 60 degrees. Because the board edge line is at a certain distance from the center of the through hole, the cutting angle of the milling cutter is changed, and the board thickness is extremely small, and the copper in the hole is not easy to be pulled out. The simultaneous improvement of small batch pcb design and production can greatly improve the production yield of PCB half-hole boards.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]