About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2021-04-07 17:39:14

date:2021-04-07 17:39:14

In the process of SMT patch processing, it is inevitable to encounter some PCBA disk surface pollution. Under normal circumstances, it is relatively easy to deal with, but when such problems occur in PCBA processing manufacturers, it is necessary to calculate the cost. Manpower and time will be wasted to a certain extent, so today we will take a look at how to deal with ENIG plate flux contamination.

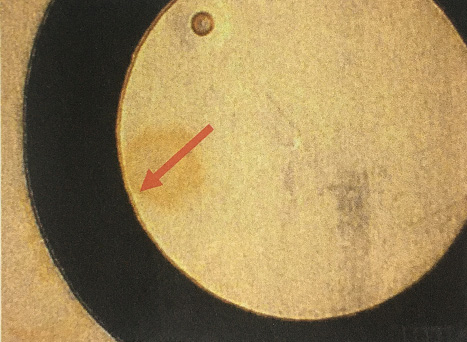

Bad case:

There is a burnt yellow stain on the ENIG disk, which can be washed off with alcohol or erased with an eraser, as shown in the figure below.

Bad reasons:

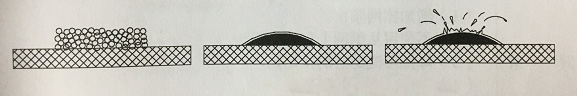

The contaminated spot is the spatter of the flux, which occurs when the solder just condenses, as shown in the figure below. The main reasons are:

(1) The solder paste absorbs moisture (there will be serious splashing at 90%RH for 20 minutes).

(2) Generally, the higher the activity of the flux, the faster its wetting rate, and the easier it is to spatter.

(3) When the solder paste melts under the large-size lead, it is easy to fly out of the solder.

Solution:

(1) Control the workshop environment to ensure that the solder paste in front of the furnace is in an environment where the relative humidity is lower than 65%.

(2) Extend the preheating time and reduce the heating rate above the melting point (corresponding to the point of occurrence).

(3) Ensure that the SMT reflow welding exhaust system works well. Flux splashing is inevitable for some time, and effective exhaust air tends to draw away the flying flux instead of spinning it around in the furnace.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]