About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2019-07-29 11:03:51

date:2019-07-29 11:03:51

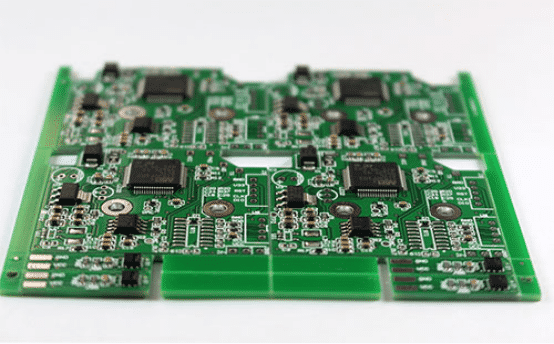

How to effectively control the prototype PCB assembly SMT quality?

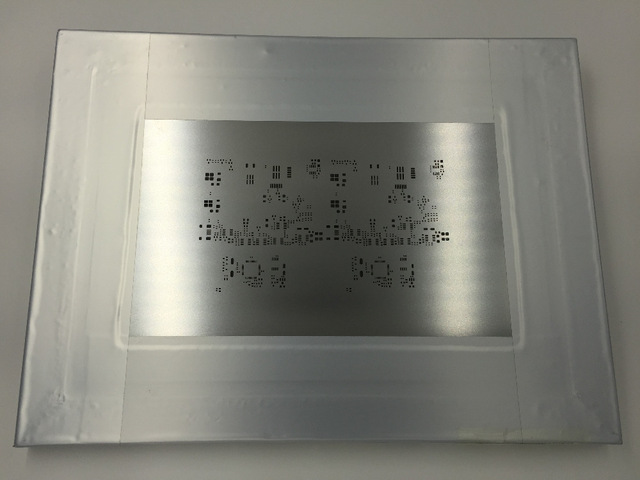

First, the steel stencil production

The solder paste is printed on the corresponding pad of the prototype PCB assembly through the steel stencil. The quality of the steel stencil has a very important influence on the welding effect of the PCB pad. The defects such as more or less tin have great relationship with the opening size of the steel stencil.

The BGA stencil opening needs to be adjusted according to the size and gap of the BGA chip pin sphere, and it is adjusted reasonable value between the virtual soldering and the short circuit.

PCB manufacturer's products mostly use BGA package specifications, must refer to the chip situation, can not be handled according to the general situation (recommended opening ratio 88%-95%).

Pay attention to the following matters when carrying out the inspection of the steel stencil:

1. Check stencil opening ways and size to meet the requirements

2. Check if the thickness of the steel stencil meets the product requirements.

3. Check if the frame size of the steel stencil is correct.

4. Check if the marking of the steel stencil is complete.

5. Check if the flatness of the steel stencil is horizontal

6. Check if the tension of the steel stencil is OK.

7. Check if the position and quantity of the stencil opening are consistent with the GERBER file.

PCB manufacturers' intact stencils can be printed with good solder paste, laying the foundation for improving the quality of the subsequent soldering.

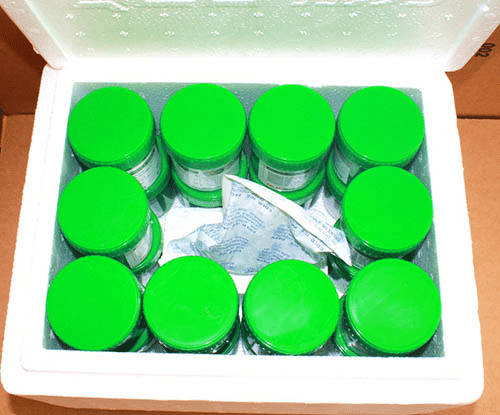

Second, solder paste control

Solder paste is used as the solder material for the prototype PCB assembly SMT process welding material. The quality of the solder paste has an important influence on the final solder quality. The solder paste must be strictly controlled.

1,Solder paste preservation

(1) The storage temperature of the solder paste is between 0 and 10 ° C. If it exceeds the storage temperature range, the temperature range of the refrigerator needs to be adjusted.

(2) The service life of solder paste is 6 months (unopened).

(3) The solder paste taken from the refrigerator should not be placed in the sunlight.

2, The usage of solder paste

(1) The PCB manufacturer must gradually increase the temperature of the solder paste to the environment temperature (25±2°C) in about 3-4 hours before opening . After the temperature is returned, the stirring time should be sufficient 1 -3 minutes, the time depending on the blender model.

(2) According to the production speed, the amount of solder paste on the steel stencil is supplemented by small amount muti-times to maintain the quality of the solder paste.

(3) Solder paste that has not been used up that day may not be placed together with unused solder paste. It should be stored in another container. After the solder paste is opened, it is recommended to use up it within 24 hours at room temperature.

(4) When using the next day, the newly opened solder paste should be used first, and the solder paste not used up the previous day and the new solder paste should be mixed and mixed in a ratio of 1:2, and added in small amount and muti-times.

(5) Change the line for more than 1 hour. Please scrape the solder paste from the steel plate before the line change to cover the inside of the solder paste can. .

(6) After 24 hours of continuous printing of solder paste, due to contamination by air dust, etc., to ensure product quality, please follow the “Step 4” method.

(7) The indoor temperature should be controlled at 22-28 °C, and the humidity RH30-60% is the best working environment.

Third, reflow oven temperature curve setting

The setting of reflow parameters is the key to affect the quality of welding. Through the temperature curve, it can provide an accurate theoretical basis for the setting of reflow furnace parameters. Each product will have corresponding temperature curve. When reflow soldering of a new product, it is necessary to re-test by the furnace temperature tester.

Key areas affecting furnace temperature:

1, the temperature setting value of each temperature zone

2, the temperature difference of each heating motor

3, the speed of the chain and mesh belt

4, the composition of solder paste

5, the thickness of the PCB board and the size and density of the components

6, the number of heating zones and the length of reflow soldering

The effective length of the heating zone and the cooling characteristics

A good furnace temperature curve is set to meet the welding parameters of the product to improve the quality of reflow soldering.

Fourth, AOI testing

AOI detectors are often placed behind the reflow soldering process. AOI can detect many defects in the previous process, such as more tin, less tin, polarity direction, tombstone and other defects. The AOI test can detect the problematic PCB board and avoid the problematic board flow in the subsequent process, which is a very important part to improve the PCBA mounting quality.

In the process of prototyping PCB assembly and SMT processing, there are many factors that affect product quality. PCB manufacturers can control the quality of PCB SMT efficiently by strictly checking the above key points.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]