About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2019-05-29 16:20:00

date:2019-05-29 16:20:00

PCBA circuit board waterproof, moisture and corrosion prevention methods

The waterproof and moistureproof of electronic products has always been a big problem, because it has no standardized and foolproof practice. It relies on the wisdom of craft engineers and the assistance of new waterproof and moisture-proof materials to achieve the goal. Generally involved in injection molding, sealing, exhaust, glue cushion, diversion, heat dissipation, deformation, mold opening and other crafts.

The relatively fragile part of the product is PCBA. Once water vapor or corrosive fluid penetrates into PCBA, it will cause short circuit or corrosion of component pins, which will affect the function of electronic products and even cause damage. PCBA waterproof, moistureproof and anticorrosive methods from the outside to the inside is usually structural protection + potting protection + PCBA functional coating protection, then I will introduce these l crafts severally .

Common waterproof and moisture-proof technology for electronic products.

First, the structure is waterproof

Structural waterproofing is the most traditional mode of waterproofing of electronic products. It should also be the first method that most engineers think of. The main idea is to dredge water, stream diversion, effective isolation of external packaging and internal electrical parts, mold design of products and various seals blocking is the key point, of course, the more complex the mold the cost is more expensive. For example, in the past few years, some waterproof mobile phones were designed with earphone holes and charge interface, such as waterproof cover and sealing ring methods were adopted. It is to start from the outside to block. A considerable part of electronic products adopt this method to achieve waterproof and moisture-proof purposes.

Another method of waterproofing and moisture-proofing is the ultrasonic wave popular in the past few years. It is suitable for some electronic products with a completely closed appearance. Even if many changes are made in the structure, it is still impossible to prevent the intrusion of moisture, because the electronic products specially mobile phones, earphones, watches, and medical equipment are used very frequently, and the appearance is subject to human-induced non-human damage.The shell itself also has the risk of deformation, and the gap at the joint of the appearance will also be deformed, which becomes a potential risk.

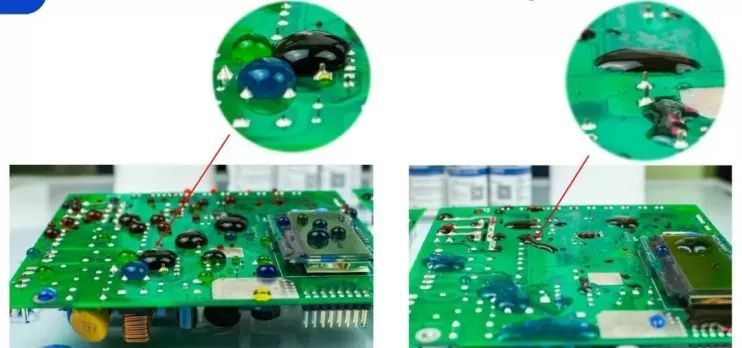

Second, potting glue waterproof

Potting method waterproofing,it is common to use epoxy resin potting glue, which is used for potting of electronic product modules. It can wrap the whole PCB board to protect it from water, moisture, salt spray, mold and earthquake, anti-external impact, etc., epoxy resin is a saturated resin. The epoxy resin potting compound produced by the substrate has high bulk strength, strong adhesive force, good weather resistance, low shrinkage, high dielectric strength and it is characterized by non-toxicity and environmental protection. It can stabilize mechanical and electrical properties at -45-120 °C after potting. It can protect the board in all directions and greatly improve the service life of the circuit board. But at the same time there are some fatal problems, such as the heat dissipation of the PCB board will be greatly affected, the most troublesome is that the product has almost no possibility of repairing, or the cost of repair is too high.

In addition to epoxy potting adhesive, silicone potting adhesive can also be used, such as high-power electronic components and motor high thermal conductivity and high temperature resistant elastic silicone potting adhesive, which is a kind of good fluidity and high thermal conductivity. Addition of room temperature two-component organic silicon rubber. Excellent electrical properties make it ideal for applications in motors, packaged power semiconductors, thyristors, rectifiers and transformers ect field and component package, as well as high-thermal conductivity, high temperature resistance, high flexibility, etc. It can be used in high-power electronic components and motors internal, especially for potting protection of module power supplies, circuit boards and insulators with high heat dissipation and temperature resistance.

Third, PCBA waterproof and moisture-proof coating

Three anti-paints

The three anti-paints are also called circuit board protection oil, coated oil, waterproof glue, insulating paint, moisture-proof paint. The three anti-paint products are generally thick, basically the coating thickness will reach 50 microns, the heat dissipation is not good, and the viscosity is high. One kilogram of output is relatively low, and drying is slow. At present, many three anti-paints still use volatile solvents, which are very harmful to the human body and the environment. This is not up to standard for some products to be exported to European and American manufacturers. If you must use it, you need to use a solvent-free environmentally friendly three-coat paint like T8507.

The potting adhesive has more protective effects on the circuit board than the three anti-paint. If you only need to play a basic protective role, you can use three anti-paint protection.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]