About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2020-10-23 17:02:51

date:2020-10-23 17:02:51

PCBA welding type

1. Reflow soldering

First of all, the first soldering process of PCBA is reflow soldering. After the SMT mounting is completed, the PCB board is reflow soldered to complete the soldering of the patch.

2. Wave soldering

Reflow soldering is the soldering of SMD components. For plug-in components, wave soldering is required for soldering. Generally, the PCB board is inserted into the components, and then the plug-in components and the PCB board are welded through the wave furnace.

3. Dip soldering

For some large-scale components or other factors that cannot pass wave soldering, a tin furnace is often used for soldering, which is simple and convenient.

4. Manual welding

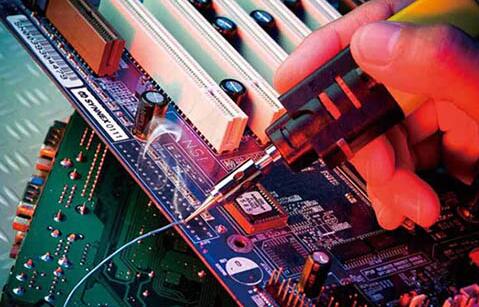

Manual soldering means that employees use electric soldering irons for soldering. Generally, manual soldering personnel are required in PCBA processing plants.

PCBA consists of multiple processes. Only through different PCBA welding types can a complete PCBA board be produced.

PCBA welding pores

The pores generated by PCBA board soldering, which is what we often call bubbles, are generally caused by reflow soldering and wave soldering during PCBA processing.

How to improve PCBA soldering porosity

1. Bake

Bake PCBs and components that have been exposed to the air for a long time to prevent moisture.

2. Control of solder paste

The solder paste contains moisture and is prone to pores and tin beads. First select a good quality solder paste. The temperature and stirring of the solder paste are strictly carried out according to the operation. The time for the solder paste to be exposed to the air is as short as possible. After the solder paste is printed, reflow soldering needs to be carried out in time.

3. Workshop humidity control

Monitor the humidity in the workshop in a planned way, and control it between 40-60%.

4. Set a reasonable furnace temperature curve

Test the furnace temperature twice a day to optimize the furnace temperature curve, and the heating rate should not be too fast.

5. Flux spraying

During wave soldering, the spraying amount of flux should not be too much and the spraying should be reasonable.

6. Optimize furnace temperature curve

The temperature of the preheating zone must meet the requirements, not too low, so that the flux can be fully volatilized, and the speed of passing the furnace cannot be too fast.

There may be many factors that affect PCBA soldering bubbles, which can be analyzed from the aspects of PCB design, PCB humidity, furnace temperature, flux (spray size), chain speed, tin wave height, solder composition, etc. It needs to be debugged many times. It is possible to get a better process.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]