About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2019-10-15 16:38:58

date:2019-10-15 16:38:58

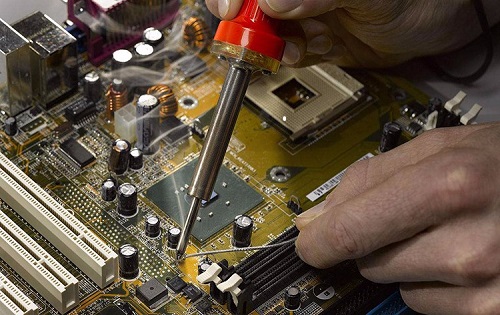

Pcb manufacturing companies electric iron operation sequence

(1) Turn on the power switch.

(2) Adjust the temperature control iron knob to the desired temperature.

(3) When the heating indicator light starts to flash, the operator of pcb manufacturing companies can take off the flame iron to start the operation.

(4) Take the tin wire in the left hand and the flame iron in the right hand.

(5) Wipe the iron tip at any time to keep the it clean.

(6) Pcb manufacturing companies technicians control the strength of the soldering iron and solder joints, and do not dig PCB pads.

(7) The angle between the soldering iron and the plane should be between 30 ° and 45 °.

(8) The working time of each solder joint should be controlled at 2-3s, and the soldering iron tip should be removed immediately after the solder melts.

(9) If the soldering piece needs to coat tin, first touch the soldering iron tip to the tin to be tinned for about 1 second, then put the solder, and immediately remove the soldering iron after the solder melts.

(10) After the welding is completed, the pcb manufacturing companies technicians should carefully check whether the solder joints are firm or not.

(11) After the operation is completed, add tin and maintain the soldering iron to the lowest temperature.

(12) Turn off the power switch.

(13) All solder joints must be cleaned with the specified cleaning agent.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]