About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2020-12-17 18:14:06

date:2020-12-17 18:14:06

Solder paste printing is the first step of SMT. If not handled properly, other follow-up links will be affected. SMT is an important part of PCB production. So, what will affect the printing quality of solder paste?

1. The quality of solder paste Solder paste is a slurry made by mixing alloy powder and flux. Regardless of whether the part can be soldered to the pad well, the quality of the solder paste is critical. The main factors that affect the viscosity of solder paste are the following: the amount of alloy powder, particle size, temperature, blade pressure, shear rate and flux activity. If the quality of the solder paste is not satisfactory, the soldering cannot be completed well, after all, the printing effect is naturally undesirable.

2. In addition to the quality of solder paste storage, the storage of solder paste is also very important. If you need to recycle and use solder paste, you must pay attention to temperature and humidity, otherwise it will affect the quality of the solder joints. Too high temperature will reduce the viscosity of the solder paste, and too much humidity will cause the solder paste to deteriorate. In addition, recycled solder paste and new solder paste should be stored separately, and used separately if necessary.

3. The stencil template is the solder paste pad needed to apply solder paste on the PCB. The quality of the template directly affects the printing quality of the solder paste. Before processing, parameters such as the thickness of the template and the opening standard must be identified. Ensure the printing quality of solder paste. The distance between the components on the PCB is about 1.27mm. For components with a distance greater than 1.27mm, the thickness of the stainless steel plate needs to be 0.2mm, and the thickness of the narrow distance needs to be 0.15-0.10mm. The thickness of the stainless steel plate depends on the conditions of most components on the PCB.

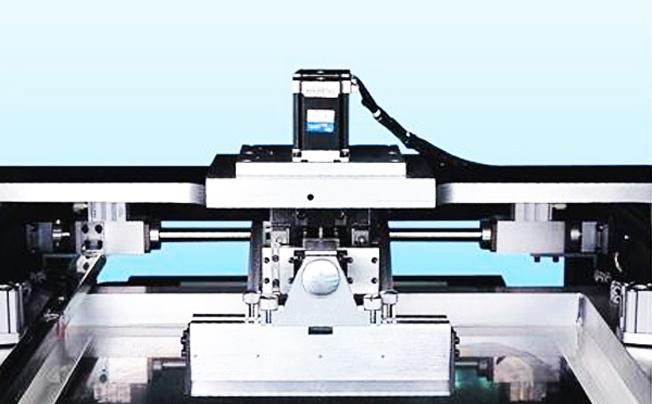

Fourth, printing equipment Printer is a device that prints solder paste on PCB templates, and has the greatest impact on process and quality. Printing machines are mainly divided into manual printing machines, semi-automatic printing machines and fully automatic printing machines. These printers have many different features and functions. According to different needs, different printing machines are used to achieve the best quality.

5. Printing method The printing method of solder paste can be divided into contact printing and non-contact printing. Printing with an open space between the screen and the printed circuit board is called non-contact printing. After setting up the machine, this distance is adjustable. Generally, the open space is 0-1.27mm; the printing method of solder paste printing without printing space is called touch printing. The touch screen can be lifted straight to minimize the impact on print quality. Especially suitable for fine and difficult solder paste printing.

6. Printing speed The high speed of the squeegee helps the rebound of the template, but at the same time prevents the solder paste from transferring to the printed circuit board pads. Too slow speed will cause the resolution of the solder paste to decrease. pad. On the other hand, the speed of the squeegee is closely related to the viscosity of the solder paste. The slower the squeegee speed, the greater the viscosity of the solder paste; similarly, the faster the squeegee speed, the lower the viscosity of the solder paste.

The conventional inspection methods of SMT: visual inspection, automatic optical inspection (AOI), electrical test (ICT) and ultrasonic inspection, etc. have been difficult to meet the density, high-speed and standardized inspection requirements of the SMT industry. X-ray inspection uses the principle of transmission imaging, using the ability of different materials to absorb and attenuate X-rays, resulting in different contrast capabilities.

X-ray inspection equipment can directly observe the location of the defect. The device has high sensitivity and good repeatability, without the need to scrap analysis samples. For experienced failure analysts, failure modes can be determined quickly and accurately. In the production process of SMT components, we can use X-ray inspection equipment to detect product failure modes more intuitively and quickly, and take corrective measures in time to prevent problems from expanding. The use of X-ray inspection equipment to monitor the production process can not only be used for solder joint inspection after reflow soldering, but also can monitor the quality of the patch before reflow soldering, so that the component position on the circuit board can be corrected in time to prevent soldering problems.

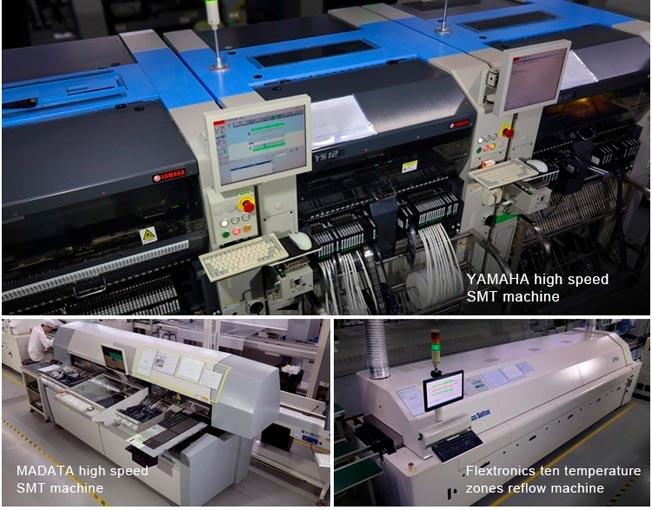

FASTPCBA select the best high-quality material suppliers to ensure our products' quality,with purchasing good solder paste such as senju,alpha,loctite etc. Everything we have done is for the benefit of ourcustomers.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]