About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2019-10-25 16:06:38

date:2019-10-25 16:06:38

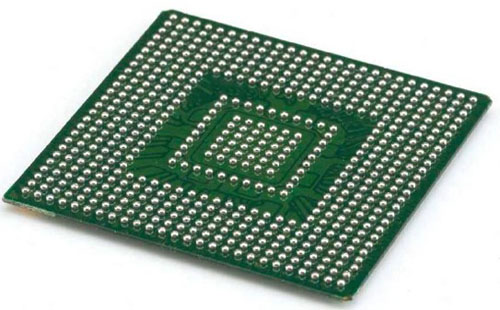

Prototype pcb manufacturing BGA package category and process characteristics

The BGA package is available in PBGA, TBGA, CBGA, FBGA and other categories. PBGA and CBGA will undergo "dynamic deformation" during welding due to the different layered structure of the package and the coefficient of thermal expansion (CTE) of each layer of material. That is, Deformation will occur with increasing temperature during the re-flow soldering of prototype pcb manufacturing due to warping.

Poor soldering of BGA is related to the dynamic deformation of BGA and PCB.

The direction of dynamic deformation and the amount of deformation (warpage) of the dynamic deformation mainly depend on the specific package structure of the BGA - the size of the package and the silicon wafer size, and also the degree of moisture absorption. To master the processability of a specific BGA, you must understand its package structure.

Dynamic deformation is a physical phenomenon. Due to the different CTE of the BGA packaging material, deformation will always occur as the temperature increases. In the production of prototype pcb manufacturing, we have no way to eliminate the deformation of BGA. What we can do is to reduce the damage caused by BGA deformation and not to aggravate the deformation of BGA.

My personal experience are as below:

(1) Increase the amount of solder joints of BGA corner joints, compensate for deformation or increase the total amount of prototype pcb manufacturing flux.

(2) Drying treatment before BGA is on-line to reduce the dynamic deformation range of BGA. It must be clear that the qualifications defined in the humidity indicator card in the package are based on the criteria that moisture absorption does not cause BGA “layering or popcorn”. However, for the BGA, even if the moisture absorption does not cause the BGA to "layer" or "popcorn", it may cause great dynamic deformation, which may cause BGA welding problems.

(3) Use a tray to reduce the stress superposition caused by PCB deformation.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]