Three aspects of PCB circuit board connection

date:2020-09-04 16:47:25

date:2020-09-04 16:47:25

PCB circuit boards are the basic components of electronic products, and any electronic product needs a circuit board to be made. PCB circuit boards must be connected to other devices in electronic products. This is the interconnection of PCBs. In general, there are three aspects of PCB connection: chip to PCB, PCB internal, PCB and external components.

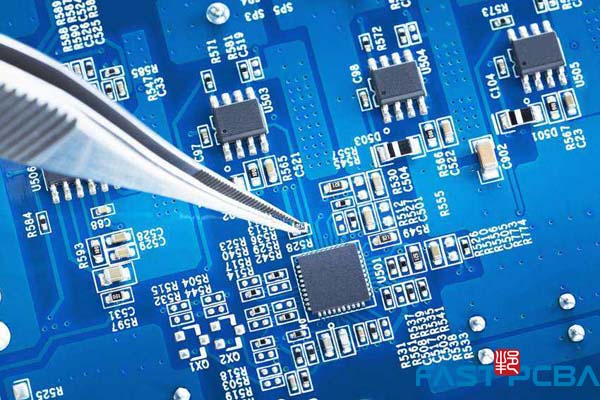

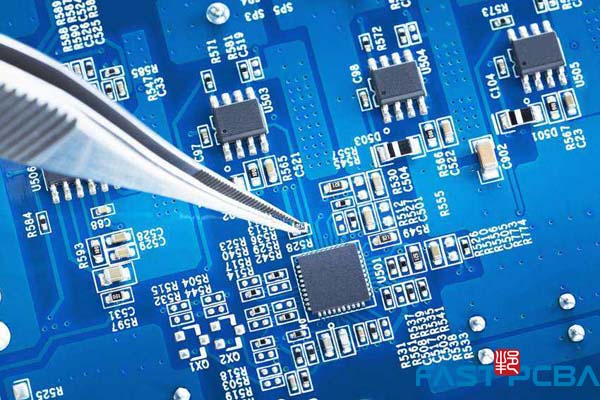

1. The interconnection of the chip and the PCB circuit board

The problem of the interconnection between the chip and the PCB is that the interconnection density is too high, which will cause the basic structure of the circuit board material to become a factor limiting the growth of the interconnection density. The solution is to use the local wireless transmitter inside the chip to transmit the data to the adjacent circuit board.

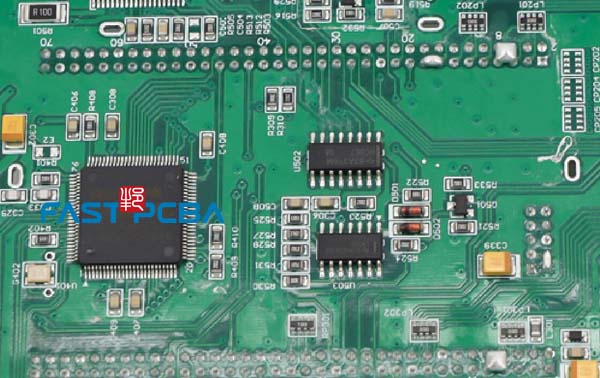

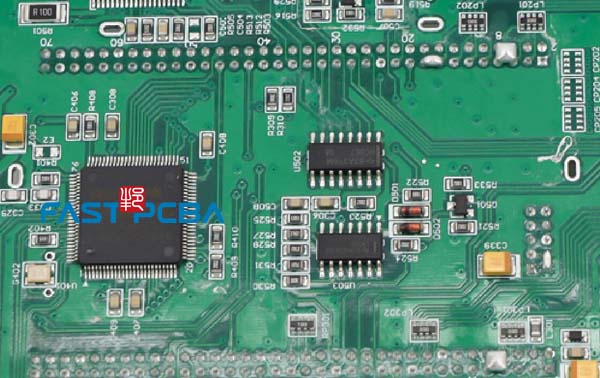

2. The internal interconnection of the PCB circuit board

The interconnection in the PCB circuit board should follow these principles: use high-performance circuit boards, whose insulation constant values are controlled in layers to manage electromagnetic fields. Avoid using components with leads, and avoid using via processing technology on sensitive boards, because this process will cause lead inductance at the vias. Choosing electroless nickel plating or immersion gold plating process can provide better skin effect for high frequency current.

3. The external connection of the PCB circuit board

There are four main types of external connections:

1) Wire welding

Use wires to directly weld the external connection points on the PCB printed board with the components or other parts outside the board, without any connectors.

2) Flat wire welding

This method is often used for the 90-degree connection between two printed boards, which becomes a whole PCB printed board component after connection.

3) Printed board socket

In more complicated instruments and equipment, this connection method is often used. The printed plug is made from the edge of the PCB printed board, and the plug part is designed according to the size of the socket, the number of contacts, the distance of the contacts, the location of the positioning hole, etc., to match the special PCB printed board socket.

4) Standard pin connection

This method is suitable for use in small instruments. Two printed boards are connected through standard pins. The two printed boards are generally parallel or perpendicular.

Keyword: PCB, PCB manufacturer, printed circuit board, pcb assembly

FASTPCBA 20 years' experience for PCB Assembly.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]

date:2020-09-04 16:47:25

date:2020-09-04 16:47:25

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]