About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2020-09-24 17:15:33

date:2020-09-24 17:15:33

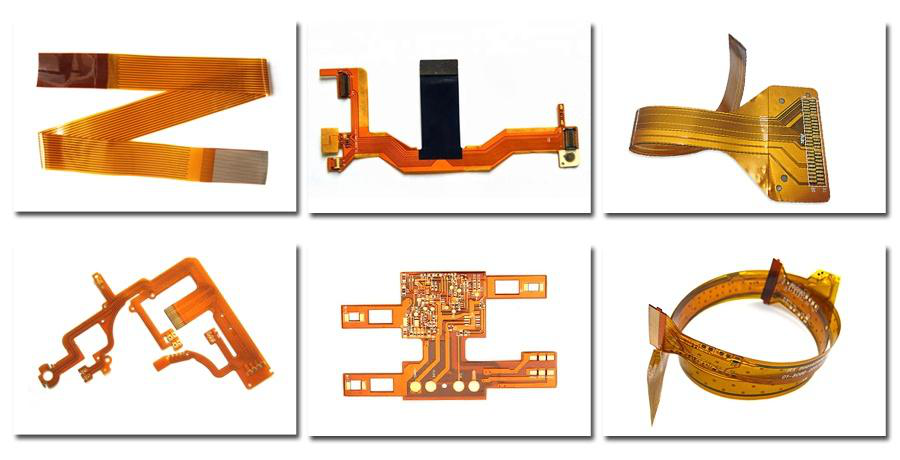

Flexible Printed Circuit (FPC) It is made of conductive circuit patterns by using light imaging pattern transfer and etching process on the surface of a flexible substrate. The surface and inner layers of double-sided and multilayer circuit boards are metalized The hole realizes the electrical connection between the inner and outer layers, and the surface of the circuit pattern is protected and insulated by PI and the glue layer.

Mainly divided into: single-sided pcb, hollow pcb, double-sided pcb, multilayer pcb, rigid-flex pcb.

Features of Flexible Printed Circuit

1. Short: short assembly hours, all lines are configured, eliminating the need for redundant cable connections;

2. Small: Smaller than PCB (hard board), it can effectively reduce the product volume and increase the convenience of carrying;

3. Light: lighter than PCB (hard board) can reduce the weight of the final product;

4. Thin: Thinner than PCB (hard board), it can improve the flexibility and strengthen the three-dimensional assembly in a limited space.

Advantages of Flexible Printed Circuit

Flexible printed circuit boards are printed circuits made of flexible insulating substrates, and have many advantages that rigid printed circuit boards do not have:

1. It can be bent, wound, and folded freely, and can be arranged arbitrarily according to the space layout requirements, and can be moved and stretched arbitrarily in three-dimensional space, so as to achieve the integration of component assembly and wire connection;

2. The use of FPC can greatly reduce the volume and weight of electronic products, and is suitable for the development of electronic products in the direction of high density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communications, laptops, computer peripherals, PDAs, digital cameras and other fields or products;

3. FPC also has the advantages of good heat dissipation and solderability, easy assembly and low overall cost, etc. The design of soft and hard combination also makes up for the slight deficiency of the flexible substrate in the component carrying capacity to a certain extent.

Main raw materials of Flexible Printed Circuit

The main raw materials are: 1. substrate, 2. cover film, 3. reinforcement, 4. other auxiliary materials.

1. Substrate

1.1. Adhesive substrate

Adhesive substrates are mainly composed of three parts: copper foil, adhesive and PI. There are two types of single-sided substrates and double-sided substrates. The material with only one side of copper foil is single-sided substrate, and the material with double-sided copper foil is double Surface substrate.

1.2. No glue substrate

The non-adhesive substrate is the substrate without the adhesive layer. Compared with the ordinary adhesive substrate, the middle adhesive layer is missing, and it is composed of only two parts: copper foil and PI, which is thinner than the adhesive substrate , Better dimensional stability, higher heat resistance, higher bending resistance, better chemical resistance and other advantages, it has now been widely used.

Copper foil: At present, the thickness of commonly used copper foil has the following specifications, 1OZ, 1/2OZ, 1/3OZ, and now a thinner copper foil with a thickness of 1/4OZ is introduced, but this kind of material is currently being used in China and is making ultra-fine roads. (Line width and line spacing are 0.05MM and below) products. With the increasing requirements of customers, materials of this specification will be widely used in the future.

2. Cover film

It is mainly composed of three parts: release paper, glue, and PI. Only the glue and PI remain on the product. The release paper will be torn off during the production process and will no longer be used (its role is to protect the glue with foreign matter).

3. Reinforce

It is a specific material used for Flexible Printed Circuit and used in a specific part of the product to increase the support strength and make up for the "soft" characteristics of FPC.

At present, the commonly used reinforcement materials are as follows:

FR4 reinforcement: The main components are glass fiber cloth and epoxy resin glue, which are the same as the FR4 material used in PCB;

Steel sheet reinforcement: The composition is steel, which has strong hardness and support strength;

PI reinforcement: the same as the cover film, it consists of three parts: PI and release paper, except that the PI layer is thicker. It can be produced from 2MIL to 9MIL.

4. Other auxiliary materials

Pure glue: This adhesive film is a heat-curing acrylic adhesive film composed of protective paper/release film and a layer of glue. It is mainly used for layered boards, Rigid-flex PCB, and FR-4 /Steel sheet reinforcement board, play a role in bonding.

Electromagnetic protective film: Paste on the board surface for shielding.

Pure copper foil: only composed of copper foil, mainly used for hollow board production.

There are 6 types of flexible circuit boards:

A. Single Side PCB: Only one side has a circuit.

B. Double Sided PCB: There are lines on both sides.

C. Hollow board: also known as window board (opening on the finger surface).

D. Layered board: two-sided circuit (separate).

E. Flexible PCB: More than two layers of circuits.

F. Rigid-flex PCB: a combination of Flexible PCB and Rigid PCB.

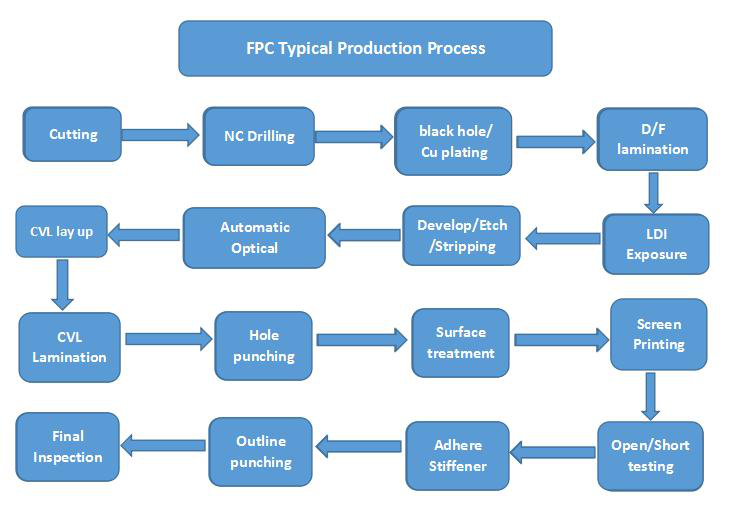

Process flow

Flexible Printed Circuit will continue to innovate from three aspects in the future, mainly in:

1. Thickness: The thickness of FPC must be more flexible and thinner;

2. Folding resistance: the ability to bend is an inherent feature of FPC, and the FPC in the future must be more resistant to folding;

3. Process level: In order to meet various requirements, the FPC process must be upgraded, and the minimum aperture and minimum line width/line distance must meet higher requirements.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]