About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2019-11-04 15:25:01

date:2019-11-04 15:25:01

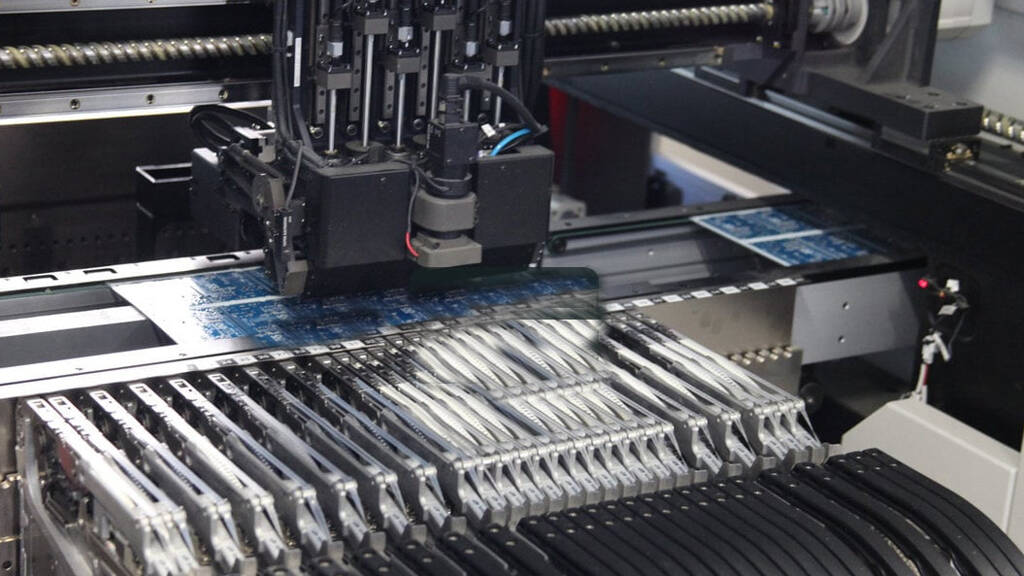

What are the typical SMT processes?

A printed circuit board assembly that is assembled using surface mount technology is called a Surface Mount Assembly (SMA). Due to the different requirements of high density, versatility and high reliability of SMA,therefore, the surface assembly components in the usual sense are often both the dip components and the SMD components. The assembly method and process flow are mainly determined by the complexity of the printed circuit board and the equipment conditions of the assembly. There are several types of surface assembly processes.

1, Single-sided assembly process

Single-sided assembly process: incoming material inspection→ Silk screen solder paste (drop patch adhesive) →SMT→ drying (curing) → reflow soldering / wave soldering → cleaning → detection→ repair

2, Double-sided assembly process

The double-sided assembly process mainly has the following two processes.

1) Incoming material inspection → PCB A side printing solder paste→ SMT - A surface reflow soldering→ flip board - PCB B side silk screen solder paste →SMT → reflow soldering→ cleaning → inspection→ rework

This process is suitable for large surface mount devices (Surface Mounted Devices, SMD, A surface is small SMC (Surface Mounted Component) / SMD) on the B side of the PCB. The solder paste of different melting points is required on the front and back of the circuit board.

2) Incoming material inspection→ PCB A-side silk-screen solder paste-SMD-A-side reflow soldering→cleaning → flip-board→PCB B-side drop patch adhesive →curing→B-side wave soldering→cleaning→ detection→ Rework.

3. Single-sided mixing process

Surface mount components and leaded components are used in combination, and the printed circuit board is a single board.

The single-sided mixing process is: incoming material inspection→ PCB B-side patch adhesive→SMT→curing→flip board→PCB A-side DIP→wave soldering→cleaning →repair

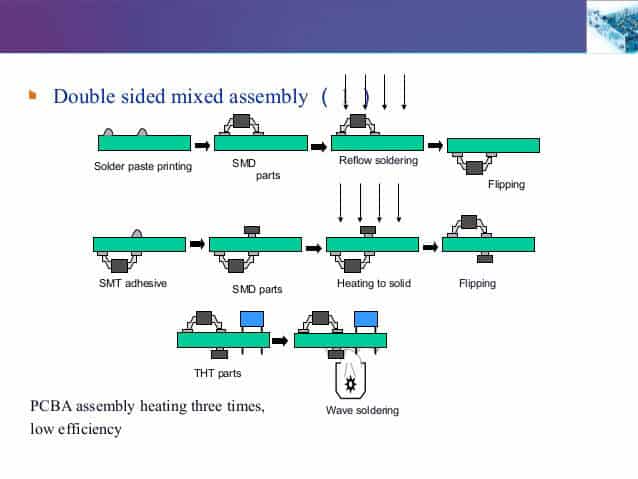

4. Double-sided mixing process

The surface mount component and the through-hole plug-in component are mixed, and the printed circuit board is a double panel.

The double-sided mixing process is: incoming material inspection → PCB A-side silk-screen solder paste → SMD → A-side reflow soldering → flip board → PCB B-side drop patch adhesive → SMD → cure → flip board - PCB A side plug-in→ wave soldering → cleaning→ inspection - repair

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]