The GERBER file is an international standard gerber file format. It contains two formats: RS-274-D and RS-274-X. Among them, RS-274-D is called the basic GERBER format and must be accompanied by a D code file. Describe a picture completely; RS-274-X is called the extended GERBER format, which itself contains D code information. Commonly used CAD software can generate these two format files.

Users or corporate design departments are often only willing to provide Gerber files for circuit boards to the manufacturing department due to various considerations. Gerber files are files that can be generated by all circuit design software. They are also called stencil data in the electronic assembly industry, and gerber files in the PCB manufacturing industry. It can be said that Gerber files are the most common and widely used file format in the electronic assembly industry. Therefore, for an electronic manufacturing company, it is very important to have a computer-aided manufacturing CAM software that can process Gerber files. It can help to improve the quality of the preparation, manufacturing and testing procedures of product production.

Gerber file is the standard format of EIA, divided into RS274-D and RS274-X, among which RS274-X is the extended file of RS274-D. When conditions permit, the manufacturing department should request the user or design department to provide the Gerber file of RS274-X as much as possible, which is conducive to the production preparation of each process.

1. Application of Gerber file

Most of the processing equipment in the SMT production line is CNC equipment. Most of the characteristic data required for their programming can be obtained from the CAD design system. How to establish an organic connection and sharing between CAD design system and SMT automated processing equipment is exactly the problem we want to solve. Using Gerber files can effectively improve the efficiency and quality of electronic assembly production.

The design departments of modern electronic manufacturing companies almost all use computer CAD software for circuit design, and the production and manufacturing departments also use a large number of automated equipment such as placement machines and plug-in machines for production. However, the two departments rarely understand each other's needs, and many useful information is not available. Sharing often forms two "automated" islands between enterprises. The manufacturing department cannot use the CAD files of the design department to improve production efficiency and reduce production costs. The design department does not understand the production process and cannot improve the design level.

However, as market competition intensifies, customers require shorter product delivery cycles and control of production costs. It is urgent to establish a connection between these two islands to shorten production preparation time, strengthen defect analysis before production, and reduce Product return for repair. This requires the connection of information flow in the "automation islands" of CAD design system and production automation, and the removal of the "partition wall" between product design and product manufacturing. Using Gerber files to prepare for offline programming of the placement machine production line, generate component location maps, etc., can improve the production efficiency of electronic assembly and reduce production costs.

2. Why convert to GERBER file to PCB factory

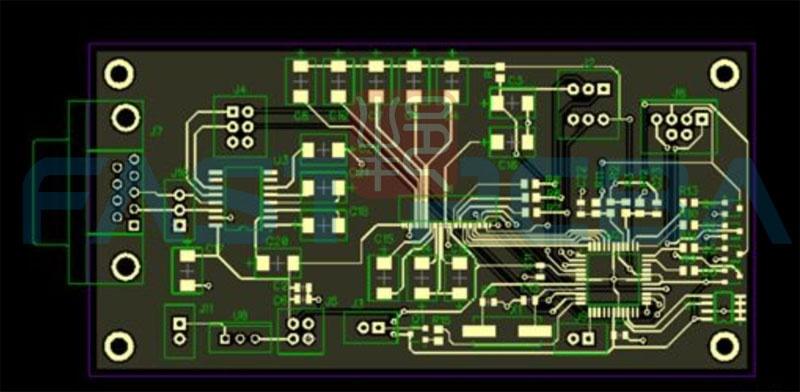

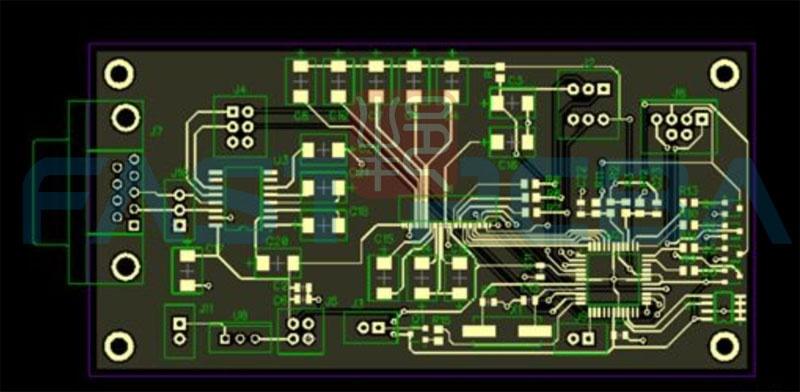

Most engineers are accustomed to designing the PCB files and sending them directly to the PCB factory for processing. However, the most popular international practice is to convert the PCB files into GERBER files and drill data and then submit them to the PCB factory.

Because electronic engineers and PCB engineers have different understanding of PCB, the GERBER file converted by the PCB factory may not be what you want. For example, you define the parameters of the components in the PCB file during design, and you don't want these parameters to be displayed. On the finished PCB, you did not explain, the PCB factory left these parameters on the finished PCB. This is just an example. If you convert the PCB file into a GERBER file, you can avoid such incidents.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]

date:2020-08-28 14:02:14

date:2020-08-28 14:02:14

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]