About us

FASTPCBA Co.,Ltd

-

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

-

F:86-13418481618

F:86-13418481618

-

[email protected]

[email protected]

date:2021-04-17 10:01:42

date:2021-04-17 10:01:42

FR1 is basically the same as FR2. FR1 has a higher TG ? ℃ of 130 instead of FR2 at 105 ?. Some laminate manufacturers that produce FR1 may not produce FR2 because the cost and usage are similar, and both are cost-effective.

FR3 is basically FR2. But instead of phenolic resin, it uses epoxy resin adhesives.

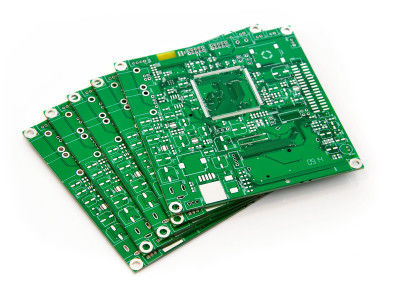

FR4 (FR = Flame Retardant) is a glass fiber epoxy laminate. It is the most commonly used PCB material. 1.60 mm (0.062 inch). FR4 uses 8 layers of glass fiber material. The maximum ambient temperature is between 120 ? and 130 ? C, depending on the thickness.

In China, FR4 is the most widely used PCB basic material, followed by FR1, and then FR2. But FR1 and FR2 are usually used for 1-layer PCBs because they are not good for through holes. It is not recommended to use FR3 to build multilayer PCBs. FR4 is the best choice. FR4 is widely used because it can make PCBs from single-layer to multi-layer very well. Using only FR4, PCB companies can manufacture various PCBs, which makes management and quality control easier, and ultimately reduces costs!

FASTPCBA OEM PCB and PCBA Manufacturer: From the above analysis, it is obvious that FR4 is the best choice for PCB production in the market. Some materials may be cheaper, but they can only be used to make single-layer boards, and the reliability of boards made of these materials is not good. Therefore, they are only used for one layer and very simple circuit boards.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

[email protected]

[email protected]