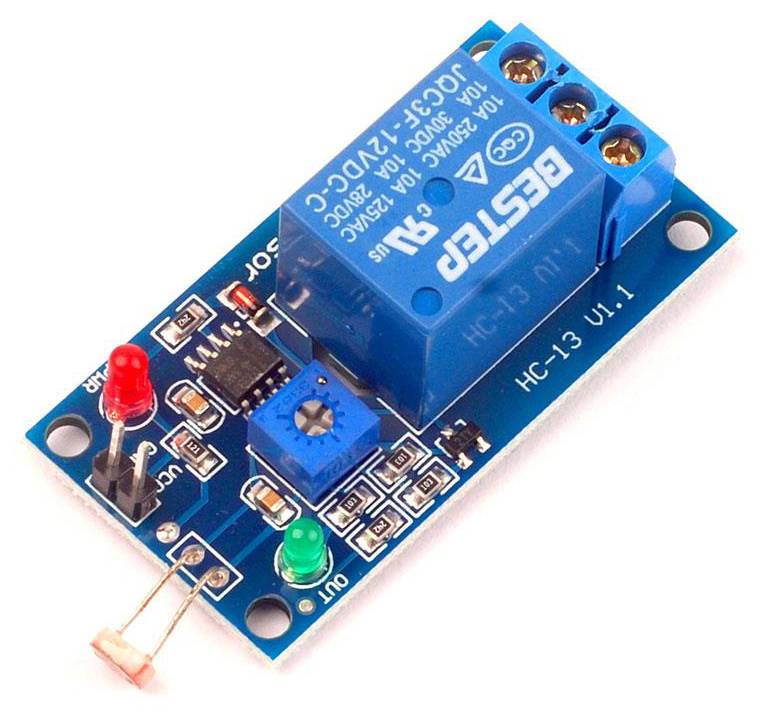

Smart electronic board for wired light sensor

Smart electronic boards apply in wired light sensor,more information pls contact: [email protected]

Email:[email protected]

Smart electronic board for wired light sensor

Light detection, brightness detection, through the potentiometer can adjust and detect the brightness of the valve point, with a relay and do a variety of brightness detection on switch, can control a variety of street lamps, can control various street lights, automatically turn on at night, automatic extinguishing during the day and vehicle supplies control and automation equipment.

Products related to this product / Related Products

- HDI pcb board fabrication and assembly

- HDI pcb board is widely used in the automotive electronics industry. HDI pcb board advantages are as below 1. Can reduce the cost of PCB: when the layers of PCB increases to more than eight layers, it is manufactured by HDI, and its cost is lower than the traditional complicated lamination process.

- Medical equipment pcb circuit board

- Medical equipment pcb circuit board Product category: Medical equipment pcb circuit board Layers: 4 layers Board thickness: 0.35mm Surface treatment: Immersion gold Process characteristics: thin plate + hole in the plate Detailed process features: inner core material. 1H / HOZ (including copper), minimum drill bit 0.15, 0.25 hole needs plated hole in plate, minimum BGA 0.2mm.

- Custom pcb printing printed circuit board maker smt pcb manufact

- Custom PCB printing, also known as circuit board printing, is a very developed new industry today, and the rapid development of screen printing has injected vitality into this industry and brought major changes to the electronics industry. The current screen printing process can fully adapt to high-density PCB production.

Related information

- Business opportunities discovered from the May Day holiday

- In PCB manufacturing,flux quality and selection

- How do PCB Manufacturers Strengthen Material Management

- Mounting machine failure analysis and troubleshooting

- PCB manufacturers requirements for flux

- FPC application and development

- In PCB manufacturing dispensing common defects and solutions

- BGA rework process

- SMC/SMID components (SsD) transportation, storage and use requirements

- Solder paste printing principle

| I want to comment: | |

| *Content: |

(Content up to 500 words, 1000 characters) |

| Verification Code: | Invisibility?! |

samples

PCB Assembly

Multilayer PCB

Rigid-Flex PCB

Flexible PCB

HDI PCB

High Frequency PCBs

Gold-Plated PCB

Aluminum PCB

PCBA Board

PCB Prototype

Components

FASTPCBA

20 years' experience for PCB Assembly.

Add WeChat:18784674559

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

3/F. 1/B, 18-2 Yuquan East Rd. Yulv Village.

3/F. 1/B, 18-2 Yuquan East Rd. Yulv Village.  F:86-18784674559

F:86-18784674559

Altogether-article comment【I want to comment】