Search Products

-

Aluminum pcb manufacturer custom pcb order quick turn pcb protot

FASTPCBA Technology Co., Ltd is a professional PCB manufacturer in China, Shenzhen. With 14 years of development, FASPCBA turns into a first class manufacturer of custom PCBmore +

-

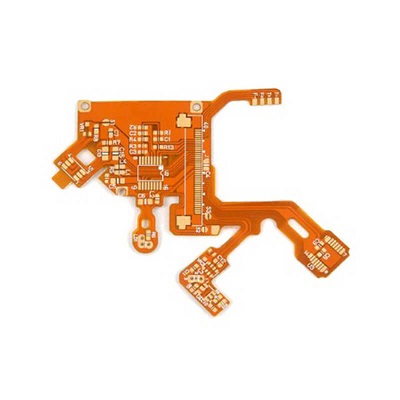

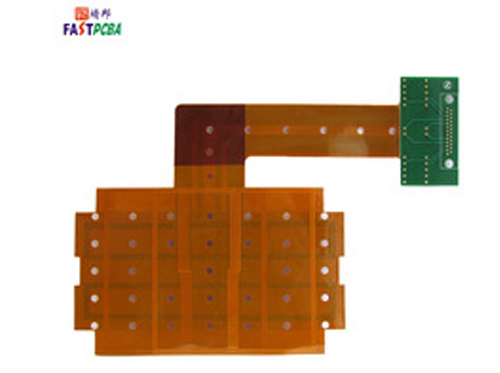

Flexible circuit board pcb order online pcb proofing

FASTPCBA Co., Ltd is a professional PCB manufacturer in China, Shenzhen. With 14 years of development, FASPCBA turns into a first class manufacturer of flexible circuit board with production capability 35,000 square meters.more +

-

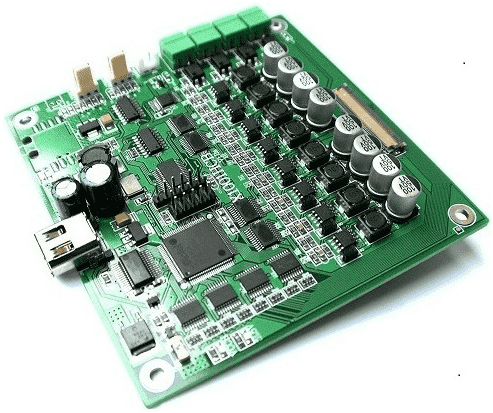

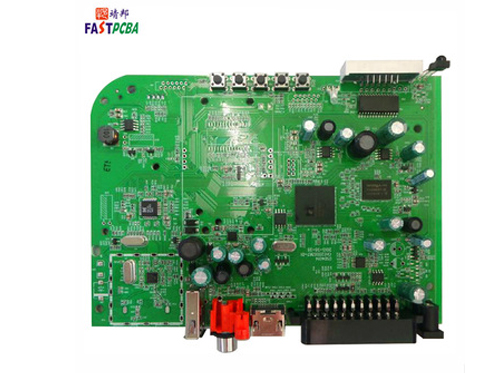

Popular custom pcb order instant pcb quote online

FASTPCBA Technology Co., Ltd is a professional PCB manufacturer in China, Shenzhen. With 14 years of development, FASPCBA turns into a first class manufacturer of HDI PCB, with production capability 35,000 square meters. FASTPCBA is providing high quality bare PCB and PCB assembly service,including components sourcing, function test,conformal coating and complete assemblyfor clients all over the world.more +

-

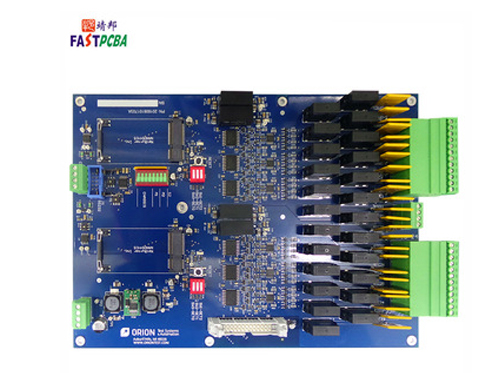

Flex pcb manufacturer pcb assembly online

FASTPCBA Co., Ltd is a professional PCB manufacturer in China, Shenzhen. With 14 years of development, FASPCBA turns into a first class manufacturer of HDI PCB, with production capability 35,000 square meters. FASTPCBA is providing high quality bare PCB and PCB assembly service,including components sourcing, function test,conformal coating and complete assemblyfor clients all over the world.more +

-

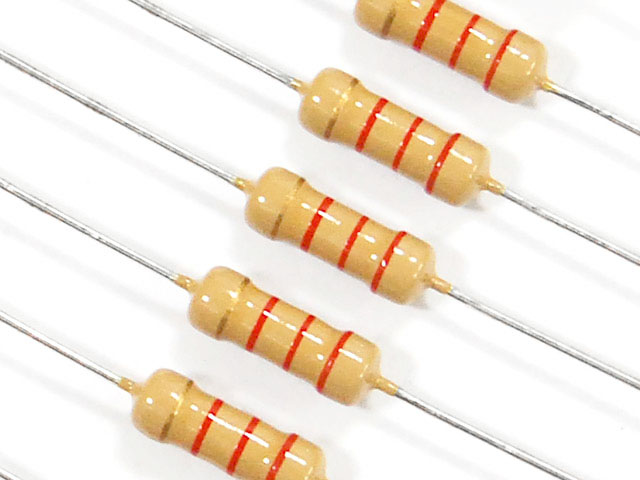

Classification of resistors

Resistors used in the manufacture of PCB electronics are typically solid resistors, thin film resistors, and wirewound resistors. Ordinary fixed resistors have only two pins, and the pins have no positive or negative polarity.more +

-

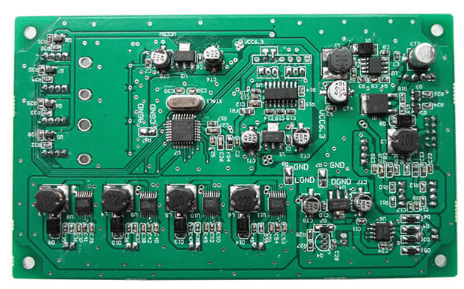

Thermal resistance alarm pcb assembly

FASTPCBA's PCB assembly is widely used in security, medical equipment, automotive electronics, smart homes, etc., and won the praise of customers. The following thermal resistance alarms are successful examples of FASTPCBA pcb assembly.more +

-

Medical infrared thermal imaging camera PCB SMT manufacturing

FASTPCBA focus on PCB SMT manufacturing, PCB assembly, PCB functional testing in a one-stop services for 15 years,our PCB involved in medical equipment, automotive electronics, IOT, smart home and other fields, who has won the ISO9001, ISO13485, IATF16949 certification, and the German Bosch audit、certified China PCB supplier.more +

-

car airconditioner pcb

Packaging Details:Seal packing for Car Fitting Solution PCB.Inner packing : Vacuum plastic packaging.Outer packing : standard carton packaging.Delivery Time:5-10 working days for Car Fitting Solution PCB.more +

-

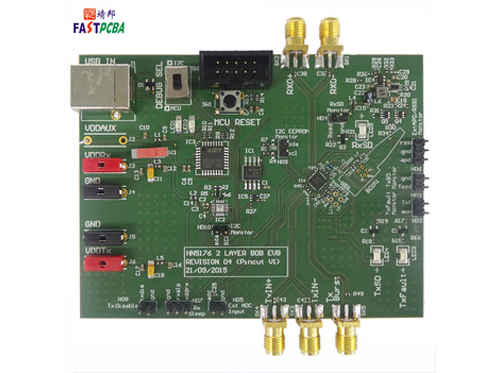

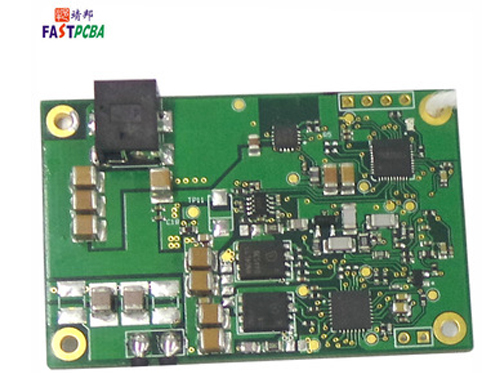

FASTPCBA-B2

Packaging Details:Seal packing for Car Fitting Solution PCB.Inner packing : Vacuum plastic packaging.Outer packing : standard carton packaging.Delivery Time:5-10 working days for Car Fitting Solution PCB.more +

-

Flexible Pcb

Packaging Details:Seal packing for Car Fitting Solution PCB.Inner packing : Vacuum plastic packaging.Outer packing : standard carton packaging.Delivery Time:5-10 working days for Car Fitting Solution PCB.more +

-

Vehicle Gps Tracker Pcb

Packaging Details:circuit board assembly.Inner packing: Vacuum packing / Plastic bag.Outer packing: Standard carton packing /ESD packing.Delivery Time:48 hours fastest deliverymore +

-

sensor pcb fabrication assembly

Packaging Details:Seal packing ;Inner packing : Vacuum plastic packaging.Outer packing : standard carton packaging. Delivery Time:5-10 working daysmore +

Search News

- [Company News]In PCB manufacturing,flux quality and selection2019/12/18/ 16:49

- The flux is the key material in solder paste for purifying the soldering surface of PCB manufacturing, improving the wettability, preventing solder oxidation, and ensuring the quality and excellent process of the solder paste. During the heating process, the flux affects the PCB pads, component terminals, and the oxide layer on the surface of the lead which function as cleaning. At the same time, it activates the metal surface.

- Read(0)

- [Company News]In PCB manufacturing dispensing common defects and solutions2019/12/09/ 15:10

- Some drip coating defects often occur in PCB manufacturing, such as wire drawing / tailing, discontinuities in glue dot size, no glue dots, and satellite dots.

- Read(0)

- [Company News]SMC/SMID components (SsD) transportation, storage and use requirements2019/11/18/ 11:38

- Unsuitable storage conditions can cause component quality to deteriorate, resulting in poor solderability. The storage conditions of SMD components must be standardized.

- Read(0)

- [Company News]Surface assembly process design principles2019/11/16/ 11:27

- Typical surface assembly methods include full surface assembly, single-sided mixing, and double-sided mixing. Full surface assembly means that both sides of the PCB are mounted components (SMC/SMD); single-sided mixing means that both the SMC/SMD and the through-hole components(THC) are on the PCB, and the THC is in the main Face, SMC/SMD may be on the main side or on the auxiliary side; double-sided mixing means that both sides have SMC/SMD, THC is on the main side, and there may be THC on both sides.

- Read(0)

- [Company News]Flux behavior in wave soldering2019/11/13/ 16:19

- During wave soldering, the flux will partially evaporate during the preheating phase, cleaning the surface to be soldered, leaving a rosin film, functions as partially separating the air and preventing oxidation.

- Read(0)

- [Company News]Selective wave soldering advantage2019/11/11/ 15:20

- Selective wave soldering is a special form of wave soldering invented to meet the requirements of modern welding processes. It also has three main components of flux unit, preheating unit and welding unit. Through pre-programmed procedures, the machine can be sprayed and welded in a targeted manner. The welding efficiency and reliability are higher than manual welding, and the welding cost is lower than wave soldering.

- Read(0)

- [Company News]PCB manufacturer's advice on controlling tin whisker growth2019/11/06/ 16:05

- At present, the most common method for inhibiting the growth of tin whiskers by PCB manufacturers is to plate the Sn layer with Ni and heat it at 150 ° C for 1~2 h for annealing to maintain the proper size of the tin grains to reduce tin fluidity in the grain boundaries of the material.

- Read(0)

- [Company News]PCB manufacturing solder paste printing common defects and solutions2019/11/05/ 16:01

- By controlling the various links of the pcb manufacturing printing process, various defects often appear in printing can be prevented. The following is a brief description of several common defects and solutions for solder paste printing.

- Read(0)

Relevant Search

Spotlight

What is difference between PCB and PCBA?

- we know that PCBA gene...

- 1What is circuit board design for manufacturability?

- 253rd Earth Day on April 22, 2022

- 3What are the classifications of dry film photoresists in pcba circuit boards?

- 4What is Halogen Free PCB Board?

- 5How to solve the problem of chip components standing up during SMT assembly?

- 6What are the standards for SMT and DIP assembly of components?

- 7Advantages and disadvantages of PCB flying probe testing

- 82022 Tomb Sweeping Day Holiday

- 9What is MCPCB?

- 10How to distinguish the number of pcb layers?

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618