Search Products

-

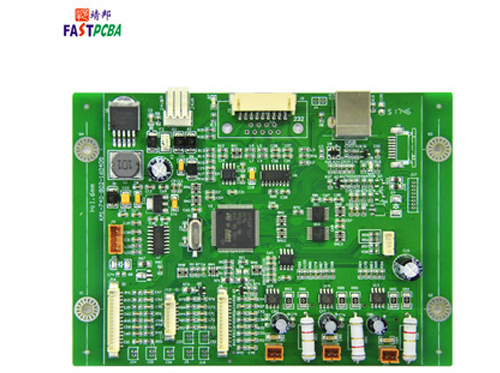

PCBA-F154

PCBA is the abbreviation of Printed Circuit Board +Assembly in English, which means that the bare pcb board mount smt components, or the whole process of DIP , referred to as PCBA. This is a common way of writing in China, and the standard writing method in Europe and America is PCB. 'A, added '', which is called the official idiom.more +

Search News

- [Company News]Business opportunities discovered from the May Day holiday2020/05/05/ 15:26

- Business opportunities discovered from the May Day holiday Time flies, the sun and the moon are like a shuttle. In a blink of an eye, the May Day holiday is nearing its end. Because of the epidemic, some people spent 5 days in small rented...

- Read(0)

- [Company News]In PCB manufacturing,flux quality and selection2019/12/18/ 16:49

- The flux is the key material in solder paste for purifying the soldering surface of PCB manufacturing, improving the wettability, preventing solder oxidation, and ensuring the quality and excellent process of the solder paste. During the heating process, the flux affects the PCB pads, component terminals, and the oxide layer on the surface of the lead which function as cleaning. At the same time, it activates the metal surface.

- Read(0)

- [Company News]How do PCB Manufacturers Strengthen Material Management2019/12/14/ 09:55

- How do PCB Manufacturers Strengthen Material Management, you will get answer from this article, and your good suggestion is welcomed

- Read(0)

- [Company News]Mounting machine failure analysis and troubleshooting2019/12/13/ 14:15

- Whether the placement machine operate normal or not directly affects the placement quality and PCB manufacturing output. In order to run normally of machine, it is necessary to fully understand the structure and characteristics of the machine, to grasp the manifestations of the machine prone to various failures, the causes of failures, and the troubleshooting methods. Only by timely discovering the problem, finding out the cause, correcting and solving the problem in a timely manner, can the machine exert its proper placement efficiency.

- Read(0)

- [Company News]PCB manufacturers requirements for flux2019/12/12/ 14:42

- In the welding process, the substances that can purify welding metal and the welding surface and help welding are called flux. PCB manufacturer physical and chemical properties requirements of flux

- Read(0)

- [Company News]In PCB manufacturing dispensing common defects and solutions2019/12/09/ 15:10

- Some drip coating defects often occur in PCB manufacturing, such as wire drawing / tailing, discontinuities in glue dot size, no glue dots, and satellite dots.

- Read(0)

- [Company News]BGA rework process2019/12/07/ 10:21

- Since the solder joint of the BGA is at the bottom of the device, it is invisible, so it is more difficult to rework compared to QFP and other peripheral pins. It is not a big problem when disassembling the BGA. However, when re-soldering the BGA, the rework system is required to be equipped with a spectroscopic vision system (also known as the bottom reflection optical system) to ensure accurate centering when mounting the BGA. The equipment suitable for rework BGA includes hot air rework station, infrared heating rework station, hot air Infrared rework system, etc.

- Read(0)

- [Company News]SMC/SMID components (SsD) transportation, storage and use requirements2019/11/18/ 11:38

- Unsuitable storage conditions can cause component quality to deteriorate, resulting in poor solderability. The storage conditions of SMD components must be standardized.

- Read(0)

- [Company News]Solder paste printing principle2019/11/15/ 11:06

- Solder paste printing is the first step in the SMT assembly process, and its function is to distribute solder paste. Solder paste printing process is the core process of SMT, which determines the process quality of SMT.

- Read(0)

- [Company News]Wave soldering process parameter setting requirements2019/11/14/ 11:26

- Frequently debugging wave soldering process parameters include component surface preheating temperature, soldering surface preheating temperature, soldering temperature, contact time (also called soldering time)

- Read(0)

- [Company News]Flux behavior in wave soldering2019/11/13/ 16:19

- During wave soldering, the flux will partially evaporate during the preheating phase, cleaning the surface to be soldered, leaving a rosin film, functions as partially separating the air and preventing oxidation.

- Read(0)

- [Company News]PCB manufacturing reflow soldering process requirements2019/11/11/ 15:08

- Reflow soldering is a key process for PCB manufacturing SMT and must be carried out under controlled conditions. The process requirements for reflow soldering are as follows.

- Read(0)

- [Company News]SMD adhesive composition, storage and use process requirements2019/11/09/ 11:16

- The SMD adhesive is usually composed of a matrix resin, a curing agent, and a curing accelerator, a toughening agent, a filler etc.

- Read(0)

- [Company News]Pcb manufacturing affecting solder paste printing factors2019/11/08/ 11:35

- The factors that pcb manufacturing affects solder paste printing include three aspects, namely solder paste performance, stencil and printing process.

- Read(0)

- [Company News]Printed circuit board reliability affecting factor2019/11/07/ 15:34

- Printed circuit board reliability depends on three aspects: 1. Design - poor design buried inherent reliability issues; 2. Manufacturing - solder joint integrity and microstructure (influencing factors during manufacturing); 3. Use - application environmental stress (deterioration factor in use)

- Read(0)

- [Company News]Prototype pcb manufacturing good joints mechanical properties2019/11/06/ 15:55

- The four most important characteristics of the prototype pcb manufacturing joint are: shear strength, creep, isothermal fatigue and thermomechanical fatigue. By combining the meanings of these four characteristics, a complete performance information of the solder joint can be obtained.

- Read(0)

- [Company News]PCB fabrication reflow process advantages2019/11/05/ 15:37

- Choosing the right pcb fabrication welding process has a large impact on the quality of the solder joints after assembly. Which process is selected is mainly based on the assembly density of PCB printed circuit boards and SMT production line equipment conditions.

- Read(0)

- [Company News]Electronic circuit board manufacturng 5s management2019/11/02/ 11:44

- 5s management is the basis of on-site management. The 5s management originated in Japan and refers to the effective management of production factors such as personnel, machines, materials and methods at the production site. This is a unique management method for Japanese companies. Since Seiri, Seiton, Seiso, Seiketsu, and Shitsuke are the first letters of the Japanese alphabet, the first letter of the Roman alphabet is "S", so it is simply referred to as 5s.

- Read(0)

- [Company News]SMT manufacturing advantages2019/10/31/ 18:09

- SMT manufacturing surface mount components are much smaller than traditional through-hole components. In general, the surface assembly technology can reduce the size of electronic products by about 60% and reduce the weight by about 80%.

- Read(0)

Relevant Search

Spotlight

What is difference between PCB and PCBA?

- we know that PCBA gene...

- 1What is circuit board design for manufacturability?

- 253rd Earth Day on April 22, 2022

- 3What are the classifications of dry film photoresists in pcba circuit boards?

- 4What is Halogen Free PCB Board?

- 5How to solve the problem of chip components standing up during SMT assembly?

- 6What are the standards for SMT and DIP assembly of components?

- 7Advantages and disadvantages of PCB flying probe testing

- 82022 Tomb Sweeping Day Holiday

- 9What is MCPCB?

- 10How to distinguish the number of pcb layers?

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618