Search Products

-

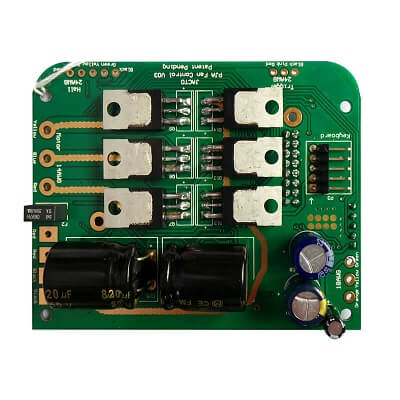

Prototype pcb soldering circuit board manufacturing pcb assembly

FASTPCBA Technology Co., Ltd is a professional rigid flex PCB manufacturer in China, Shenzhen. With 14 years of development, FASPCBA turns into a first class manufacturer of prototype PCBmore +

-

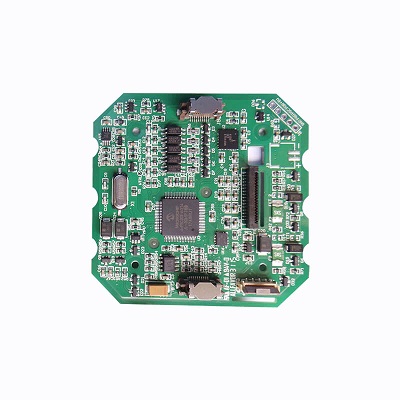

Prototype pcb soldering no MOQ small batch pcb one-stop service

FASTPCBA Co., Ltd is a professional one-stop PCB manufacturer in China, Shenzhen. With 15 years of development, FASPCBA focus on small batch PCB prototype, with production capability 50,000 square meters.more +

Search News

- [Company News]Flux behavior in wave soldering2019/11/13/ 16:19

- During wave soldering, the flux will partially evaporate during the preheating phase, cleaning the surface to be soldered, leaving a rosin film, functions as partially separating the air and preventing oxidation.

- Read(0)

- [Company News]SMT manufacturing 10 self-test steps for ESD protection2019/10/16/ 02:47

- Check your own station to ensure that there are no static objects (such as plastic bags) or static electricity generating tools on the SMT manufacturing workbench......

- Read(0)

- [Company News]PCB soldering of PCB manufacturers2019/10/14/ 18:37

- PCB soldering ofPCB manufacturers Pcb manufacturing wave soldering principle Wave soldering process and equipment wave soldering was first invented by Fry's Metal Company of the United Kingdom in the 1950s. It is the most mature, most infl...

- Read(0)

- [Company News]PCBA manufacturer make circuit board impedance reasons2019/08/23/ 11:25

- The impedance of the PCB board refers to the resistance and the parameters of the reactance, which hinder the AC. Impedance processing is essential in PCB board production. Why do PCBA manufacturers have to make impedance to the pcb board? The following FASTPCBA PCB manufacturers introduce to you simply.

- Read(0)

- [Company News]PCB manufacturing selective soldering technics difficulties2019/08/22/ 10:43

- In the PCB manufacturing electronics industry welding technics, more and more pcb manufacturers are turning their attention to selective welding. Selecting welding can complete all the solder joints at the same time, so that the production cost is minimized, and the reflow soldering is overcome the problem of temperature-sensitive components affected, and the selective soldering is also compatible with future lead-free soldering. These advantages make the range of applications for soldering wider and wider.

- Read(0)

- [Company News]During the Pcb manufacturing process, what are the details that must be paid attention to?2019/07/02/ 15:51

- During the Pcb manufacturing process, what are the details that must be paid attention to? Inside each production plant, there will be an SMT processing line. On this line, we can divide into the following sections. ...

- Read(0)

- [Company News]About the thermal design of PCBA2019/06/27/ 09:00

- About the thermal design of PCBA PCBA welding uses hot air reflow soldering, which relies on the convection of the wind and the conduction of PCBs, welding pads, and leads. Due to the different thermal capacity of th...

- Read(0)

- [Company News]How to solder SMT components with different solder paste heights2019/06/10/ 10:33

- How to solder SMT components with different solder paste heights The growing demand for micro-components in SMT consumer electronics is forcing industrial electronics designers to use smaller component capsulation. &...

- Read(0)

- [Company News]Popular Science: Understanding of PCB soldering Flux Correctly2019/04/17/ 15:47

- In the welding process, the material that can clean the welding metal and the welding surface and help the welding is called flux. Flux is an indispensable craft material in the soldering process. Liquid flux is used in wave soldering and manual soldering processes. Flux and solder are used separately. In the reflow process, the flux is an important part of the solder paste. The quality of the solder is not only related to the solder alloy, components, PCB quality, soldering process, but also has a very important relationship with the performance of the flux and the flux choosing .

- Read(0)

- [Company News]About Soldering Tin2019/02/26/ 14:00

- Soldering tin is an important industrial raw material for welding electronic components. It is a low melting point metal solder, that mainly refers to the solder made of tin-based alloy. 1. Function and Moisture ...

- Read(0)

- [Company News]Pcb welding quality inspection2018/11/16/ 16:53

- 1) Visual inspection Check whether the welding quality is qualified, whether it is leaking, whether there is flux around the solder joint, whether there is continuous welding, bridge welding, whether the pad has cracks, whether the sol...

- Read(0)

Relevant Search

Spotlight

What is difference between PCB and PCBA?

- we know that PCBA gene...

- 1What is circuit board design for manufacturability?

- 253rd Earth Day on April 22, 2022

- 3What are the classifications of dry film photoresists in pcba circuit boards?

- 4What is Halogen Free PCB Board?

- 5How to solve the problem of chip components standing up during SMT assembly?

- 6What are the standards for SMT and DIP assembly of components?

- 7Advantages and disadvantages of PCB flying probe testing

- 82022 Tomb Sweeping Day Holiday

- 9What is MCPCB?

- 10How to distinguish the number of pcb layers?

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618

pcba13@fastpcba.cn

pcba13@fastpcba.cn