Search Products

-

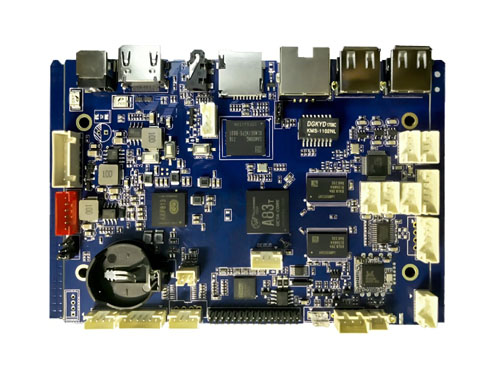

OEM PCB PCBA SMD Services Electronic Contract PCBA Manufacturer

With 20+ years of OEM printed circuit board ( PCB ) and PCB assembly manufacturing experience along with excellent quality, advanced services and competitive prices, FASTPCBA has won numerous customers' trust and support. As a professional EMS/OEM PCB PCBA Manufacturer, we could provide one-stop pcb assembly service.more +

-

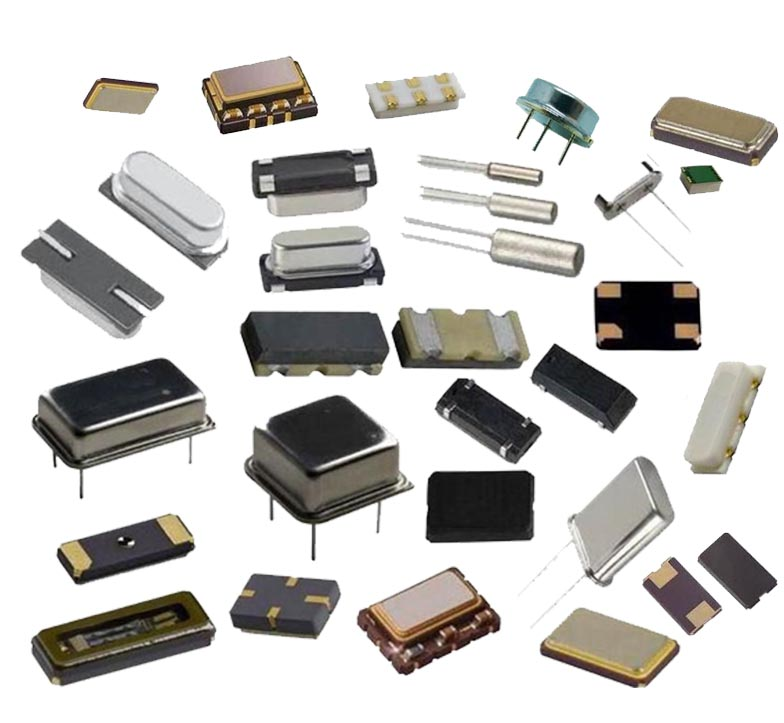

Surface mount component package category

The package structure of SMD components is the basis of process design. According to the structure of pins or solder joints, it can be divided into: Chip type J-shaped pin type, L-shaped pin type, BGA type, BTC type, castle type.more +

-

Surface mount device (SMD)

Surface-mounting devices (SMD) are developed on the basis of the original Dual Inline Package (DIP) devices. They are an important indicator for the development of through-hole technology (THT) to SMT and are also important for the development of SMT.more +

-

China pcb manufacturer of smoke temperature composite fire detec

The China pcb manufacturers’ PCB applied to smoke temperature composite fire detector which adopts the special structure design photoelectric sensor, FASTPCBA the China pcb manufacturers’ SMD mounting processing technology, with high sensitivity, stable and reliable, low power consumption, beautiful and durable, easy to use and so on. The circuit and power supply can be self-tested for analog alarm testing. China pcb manufacturer:FASTPCBA provides a one-stop service for PCB manufacturing, assembly, testing, housing packaging, and SMT processing.more +

Search News

- [Company News]Smd's reflow soldering process and the benefits of IR soldering2021/07/07/ 18:05

- After infrared heating reflow soldering, generally called infrared soldering, it is mainly used for soldering substrates with surface mount components. Generally, the substrate is transported through a machine with a series of heating elements, such as rod-shaped radiators positioned transverse to the transport direction.

- Read(0)

- [Company News]What is the process from bare PCB to PCBA?2021/04/06/ 17:51

- SMT is a Surface Mounted Technology, which is one of the most popular technologies and processes in the electronics assembly industry. Simply put, it is a kind of surface mount components without leads or short leads (SMC/SMD for short, chip components in Chinese) mounted on the surface of a Printed Circuit Board (PCB) or the surface of other substrates Above, the circuit assembly technology that is assembled by soldering and assembling by reflow soldering or dip soldering.

- Read(0)

- [Posts]What is the difference between SMD and SMT?2020/11/17/ 16:20

- Surface Mount Technology (SMT) is essentially a method of placing components on a circuit board. Modern SMT assembly technology is smaller, more efficient and faster to operate. Surface Mount Device (SMD) is the actual component mounted on the circuit board according to the specific component.

- Read(0)

- [Company News]Through Hole Reflow Process (PIHR) introduction2019/12/10/ 14:19

- Through-hole component reflow soldering process (Pin-In-Hole Reflow, PIHR) is to insert pins into the insertion hole filled with solder paste and use the reflow soldering process method to achieve through-hole components and surfaces mount components (SMC / SMD) are reflowed at the same time. Compared with traditional crafts, it has great advantages in economy and advancedness.

- Read(0)

- [Company News]SMC/SMID components (SsD) transportation, storage and use requirements2019/11/18/ 11:38

- Unsuitable storage conditions can cause component quality to deteriorate, resulting in poor solderability. The storage conditions of SMD components must be standardized.

- Read(0)

- [Company News]Printed Circuit Boards Thermal Design Introduction2019/11/16/ 11:36

- Electronic devices will get hot during work. The failure rate of electronic products increases exponentially with increasing operating temperature. In general, high temperatures can degrade insulation performance, component damage, thermal aging of materials, cracking of low-melting welds, and loss of solder joints, ultimately leading to failure of electronic equipment. The purpose of the heat dissipation design is to control the temperature of all electronic components inside the product so that it does not exceed the maximum temperature specified by the standards and specifications under the working environment.

- Read(0)

- [Company News]Surface assembly process design principles2019/11/16/ 11:27

- Typical surface assembly methods include full surface assembly, single-sided mixing, and double-sided mixing. Full surface assembly means that both sides of the PCB are mounted components (SMC/SMD); single-sided mixing means that both the SMC/SMD and the through-hole components(THC) are on the PCB, and the THC is in the main Face, SMC/SMD may be on the main side or on the auxiliary side; double-sided mixing means that both sides have SMC/SMD, THC is on the main side, and there may be THC on both sides.

- Read(0)

- [Company News]SMD adhesive composition, storage and use process requirements2019/11/09/ 11:16

- The SMD adhesive is usually composed of a matrix resin, a curing agent, and a curing accelerator, a toughening agent, a filler etc.

- Read(0)

- [Company News]What are the typical SMT processes?2019/11/04/ 15:25

- What are the typical SMT processes? A printed circuit board assembly that is assembled using surface mount technology is called a Surface Mount Assembly (SMA). Due to the different requirementsof high density, versatility and high reliabil...

- Read(0)

- [Company News]Pcb manufacturing company wave soldering joint requirements2019/10/25/ 15:54

- The requirements for soldering solder joints of pcb manufacturing companies are shown in Table 12-1 below.

- Read(0)

- [Company News]SMA preheating concerns2019/10/14/ 16:19

- The problem to be concerned during SMA preheating, the preheating temperature selection in SMA wave soldering should consider not only the activation temperature required by the flux, but also the preheating temperature required by the SMC/SMD itself.

- Read(0)

- [Company News]During Pcb manufacturing process, causes and precautions for poor welding2019/08/08/ 15:10

- During pcb manufacturing process, bridging connection is a conductive path formed by soldering two or more adjacent pads in contact with each other. The cause of bridging connection is mostly due to excessive solder or severe sag after solder printing, or the size of the substrate soldering area is over the tolerance, SMD placement offset, etc., SOP, QFP circuit tends to miniaturization stage, bridging connection causes electrical short circuit and affects product usage.

- Read(0)

- [Company News]For China pcb manufacturer, storage of surface-mounted components2019/07/17/ 17:41

- For China pcb manufacturer, surface mount components are typically in ceramic, metal, and plastic packages. The previous two packages have better air tightness, no sealing problems, and the components can be stored for a long time. However, due to the poor airtightness of the plastic packaging of SMD products, special attention should be paid to the assembled components on the plastic surface.

- Read(0)

- [Company News]SMC/SMD welding characteristics and precautions should pay attention in installation design2019/06/24/ 15:53

- SMC/SMD welding characteristics and precautions should pay attention in installation design In SMA wave soldering, the solder wave generator in the wave soldering equipment must be technically updated to meet the ...

- Read(0)

- [Company News]SMT components disassemble tips2019/06/10/ 09:38

- SMT components disassemble tips It's not easy to remove the SMT components in one minute. You need to practice more often to get more experience so that you can quickly and easily disassemble the components without damage...

- Read(0)

- [Company News]Analysis of the Causes of Component Shift in SMT Processing2019/04/16/ 14:22

- The main purpose of SMT processing is to accurately mount the surface-mount components to the fixed position of the PCB. In the process of mounting processing, some process problems occur sometimes, which affects the quality of the mounting, such as the displacement of components. The displacement of the components that appear in the processing of the mounting is a foreshadowing of several other problems in the soldering process of the component board, which needs attention. So what is the reason for components shift in the SMT processing?

- Read(0)

Relevant Search

Spotlight

What is difference between PCB and PCBA?

- we know that PCBA gene...

- 1What is circuit board design for manufacturability?

- 253rd Earth Day on April 22, 2022

- 3What are the classifications of dry film photoresists in pcba circuit boards?

- 4What is Halogen Free PCB Board?

- 5How to solve the problem of chip components standing up during SMT assembly?

- 6What are the standards for SMT and DIP assembly of components?

- 7Advantages and disadvantages of PCB flying probe testing

- 82022 Tomb Sweeping Day Holiday

- 9What is MCPCB?

- 10How to distinguish the number of pcb layers?

Home

Home FASTPCBA

FASTPCBA PCB Board

PCB Board PCB Assembly

PCB Assembly News

News Quote

Quote

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

Building 1, Senyang Electronic Technology Park, Guangming High-tech Park, Yutang Street, Guangming District, Shenzhen City.

F:86-13418481618

F:86-13418481618